Search

All search results for "Vorsprung"

(164)

At AUDI AG’s Annual Media Conference, CEO Gernot Döllner and CFO Jürgen Rittersberger presented and assessed the financial result for the 2023 fiscal year. They also offered a glimpse of the numerous models to be launched over the next two years and provided information on the company’s strategic focus. Their key statements at a glance:

With its characteristics, the electric SUV stands for Vorsprung durch Technik. The model is defined not only by impressive driving and charging performance, but also by increased efficiency and long range. The Audi Q6 e-tron embodies typical Audi SUV styling with a further refined e-tron design language. The new design philosophy in the interior and pioneering technologies debuting in the new model, begin the next chapter in electric mobility for the four Rings and make Vorsprung durch Technik a tangible experience every day. With the Q6 e-tron range, e-mobility is coming from the Ingolstadt plant for the first time. The Audi Q6 e-tron quattro and SQ6 e-tron will be available to order from March 2024 at a price of 74.700 and 93.800 euros and will be delivered to customers in the third quarter of 2024.

The PPE, developed jointly with Porsche, and the E3 1.2 electronic architecture are important milestones in the expansion of Audi's global range of electrically powered models. They mark the start of a comprehensive strengthening and rejuvenation of the model portfolio. The Q6 e-tron underpins Audi’s promise to offer electric vehicles in all core segments by 2027.

“Vorsprung durch Technik” recharged: Audi and SAIC further strengthen partnership

“Vorsprung durch Technik” recharged: Audi and SAIC further strengthen partnership

With premium products and a tailor-made ecosystem developed for the tech-savvy Chinese customer groups, Audi is recharging “Vorsprung durch Technik” and consequently building on its already strong foundation for its future growth in the world’s largest and fastest-growing EV market.

With the launch of Premium Platform Electric (PPE), Audi is introducing a completely new electronics architecture. The E³ will be used for the first time in the 1.2 specification in the Audi Q6 e-tron series. The name E³ stands for end-to-end electronic architecture. Its core element consists of five high-performance computers (high-performance computing platform, HCP) that cover all vehicle functions – from the drive system and assistance systems to the infotainment and comfort systems to the safety systems and backend connectivity.

The design: Vorsprung through design

The design: Vorsprung through design

The Audi RS Q e-tron is technically a quantum leap. And visually, the futuristic-looking prototype is also clearly different from typical Dakar vehicles. It is the result of an internal competition in the Audi Design department.

“There were many great designs,” says Juan Manuel Diaz, who is responsible for the design of the racing vehicles at Audi. “We liked Dario Tomorad’s proposal the best. Together with him and the whole team, we have put together a fascinating car in an extremely short period of time that is completely different, but is still recognizable as an Audi at first glance.” “Most of the cars in the Dakar Rally are rather boxy,” says Dario Tomorad. “Audi is known for doing things differently. We are incorporating the dynamics of our production models to the race car. We have a coupe-like silhouette, similar to the e-tron Sportback and we’ve taken inspiration from our unique motorsport history.” Audi Sport is returning to its roots with its involvement in the Dakar Rally. The Audi quattro revolutionized rallying in the early 1980s. The distinctive angular body panel shapes of the original quattro can also be found on the Audi RS Q e-tron. The vertical fin on the rear decklid and the air intake on the roof, which supplies sufficient cooling air to the electric motors, the high-voltage battery and the energy converter, are reminiscent of Audi’s successful era in the Le Mans 24 Hours. The protrusions behind the doors are based on the side blades of the Audi R8. They have a completely different purpose on the Audi RS Q e-tron: they house the two spare wheels that are typically carried on board during the Dakar Rally. The rear of the ‘desert ship’, which the designers are particularly excited about in the dark, looks particularly futuristic: the rear edge of the fin consists of LEDs that function as brake lights. The shape of the headlights and tail lights are also typically Audi. The Audi RS Q e-tron looks like a UFO from the front. Because the vehicles jum

Audi S8 TFSI

The Audi S8 combines progressive luxury with dynamic athleticism while honing its reputation as the benchmark for Vorsprung durch Technik with innovative suspension systems.

Images

Videos

Engine type V8 engine

Displacement in cc / bore x stroke in mm / compression 3996 / 86.0 x 86.0 / 10.1

Max. power output in kW (PS) / at rpm 420 (571) / 6000

Max. torque in Nm (lb-ft) / at rpm 800 (590.0) / 2050 - 4500

Top speed in km/h (mph) 250 (155.3) (governed)

Acceleration, 0-100 km/h (0-62.1 mph) 3.8

Fuel consumption, combined in l/100 km (US mpg) 11.7 - 11.4 (20.1 - 20.6)

CO2 emissions, combined in g/km (g/mi) 265 - 258 (426.5 - 415.2)

CO2 class G

Unladen weight without driver / with driver / gross weight limit in kg (lb) 2220 (4894.3) / 2295 (5059.6) / 2710 (5974.5)

The Audi Q6 e-tron is the first production model on the Premium Platform Electric (PPE) and is, therefore, the new reference for Vorsprung durch Technik. The new model is not only characterized by impressive driving and charging performance but also sets standards in terms of range and efficiency. The exterior is characterized by powerful SUV design with perfect proportions and further developed elements typical of electric vehicles from Audi. The new design philosophy in the interior and pioneering technologies making their debut in the model open the next chapter of electric mobility at Audi and make Vorsprung durch Technik a tangible experience every day. The Audi Q6 e-tron is an all-electric SUV in the premium mid-size segment and thus complements Audi's electric SUV model portfolio. With a vehicle length of 4,771 millimeters (15.6 ft), a width of 1,939 millimeters (6.4 ft) without mirrors, and a height of 1,648 millimeters (5.4 ft), the SUV offers maximum space, comfort, and, therefore, suitability for everyday use. The wheelbase of 2,899 millimeters (9.5 ft) allows plenty of legroom, especially for the second row of seats. With these dimensions, the Audi Q6 e-tron offers enough space for five passengers with luggage. The exterior is powerful, sporty, and perfectly proportioned. In the interior, a new design philosophy finds its way into series production with the Audi Q6 e-tron*.

Technology

Technology

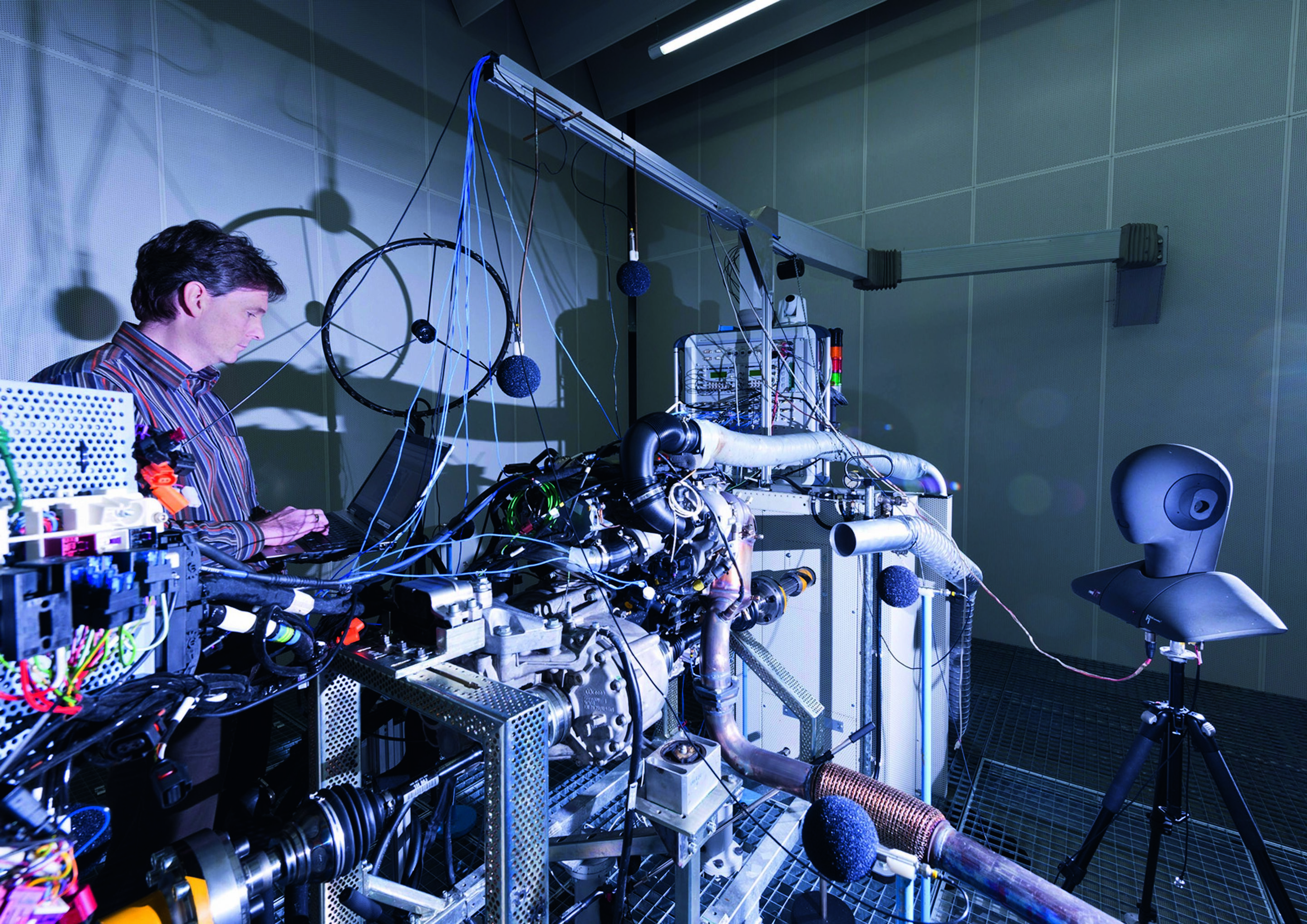

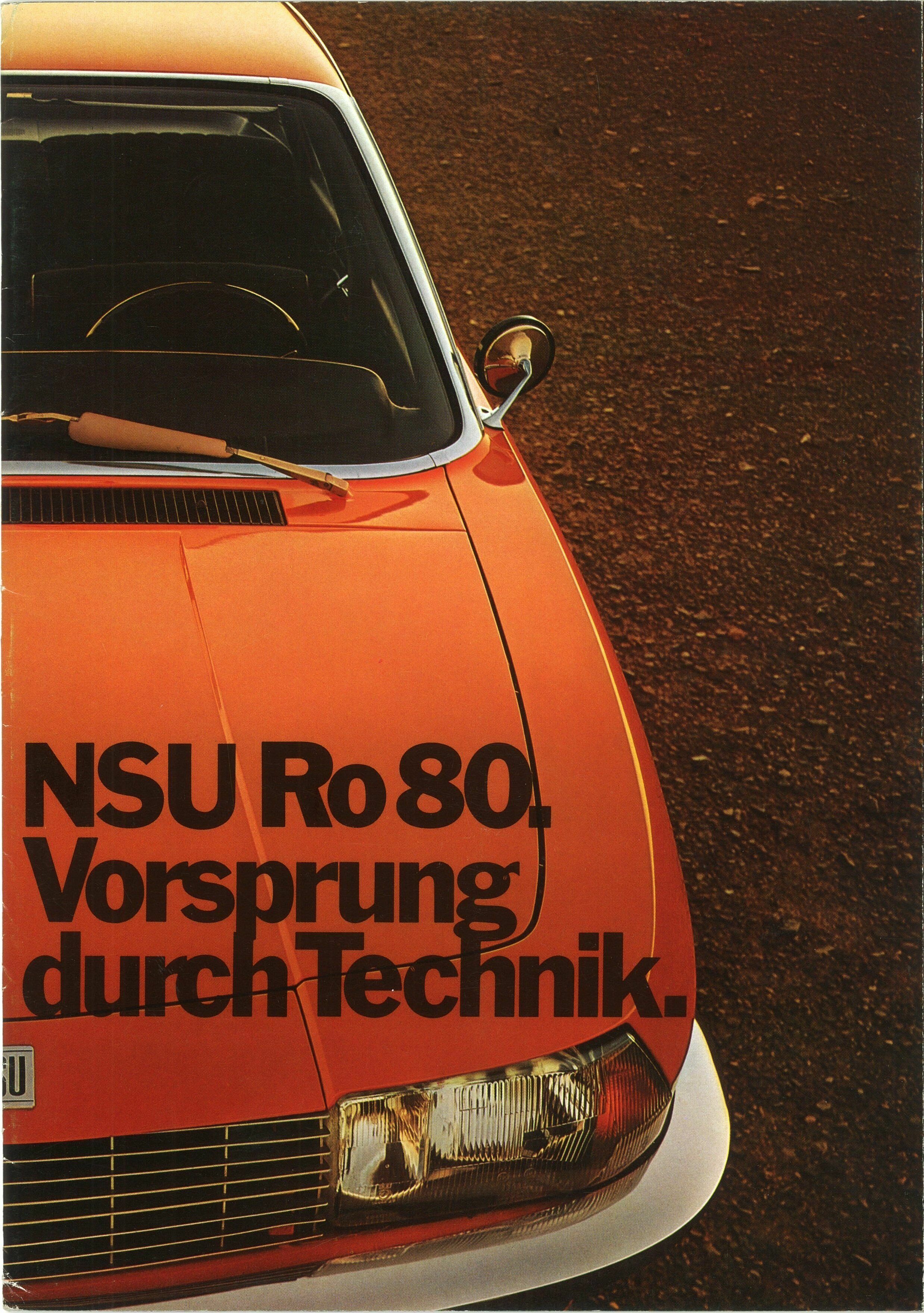

Vorsprung durch Technik is not just a slogan, it is the core of the Audi brand. For decades, technical perfection has been the goal of vehicle development – which is a dynamic process. At present, technical fields of action are being re-evaluated and redefined. Audi CEO Gernot Döllner: “We are focusing on four core areas that we are working on intensively and that will define ‘Vorsprung durch Technik’ in the future. These are design, the fields of user interface and user experience, the topic of 'quattro', i.e. traction and driving experience, and finally efficiency. With our latest generation of electric models, we are already clearly showing the way forward in efficiency.” In development, ‘software first’ applies. In the future, Audi will offer vehicles that have been developed around the software – also called software-defined vehicles (SDV).

Images

Videos