Improved efficiency, longer range: Drive system

Back to overviewThe electric drive system in the Audi Q8 e-tron meets the diverse demands that drivers place on a luxury SUV with a high-performance total package, offering superior traction, even in difficult road conditions or critical situations, thanks to the electric all-wheel drive. With its efficient powertrain, the Audi Q8 e-tron boasts dynamic driving performance and thanks to improvements to many components of the drive concept, the Q8 e-tron impresses with consumption values standard for its class, and increased range. The development team gave “the heart of the engine” a thorough update, as technical project manager Jens Müssig explains: “All the changes help to increase the range of the Audi Q8 e-tron without diminishing its sporty qualities.” This is also true of the sportiest electric luxury SUV, the Audi SQ8 e-tron. Powered by three electric motors – two on the rear axle, one on the front axle – it offers superior performance in both longitudinal and lateral dynamics with electric torque vectoring.

Three motorizations on offer

Both the Audi Q8 e-tron and the Q8 Sportback e-tron will be launched in three unique drive configurations.

Audi Q8 50 e-tron

Audi Q8 Sportback 50 e-tron: Equipped with a battery with a capacity of 89 kWh net (gross: 95 kWh), the entry-level model features one electric motor each on the rear and front axles, for a maximum system output in boost mode of 250 kW and 664 Nm of torque. The vehicle makes the 0 to 100 km/h sprint in 6.0 s. The range according to the WLTP is up to 491 km for the SUV and up to 505 km for the Sportback. The top speed is fixed at 200 km/h.

Audi Q8 55 e-tron /

Audi Q8 Sportback 55 e-tron: the battery size is 106 kWh net (gross: 114 kWh). With its two motors, the quattro drive has an output of 300 kW with a torque of 664 Nm in boost mode, enabling the vehicle to accelerate from a standstill to 100 km/h in 5.6 s. The range according to the WLTP is up to 582 km for the SUV and up to 600 km for the Sportback. Its top speed is fixed at 200 km/h.

| Audi Q8 e-tron |

|

|

| Battery energy in kWh net/gross | 89/95 | 106/114 |

| Maximum charging power in kW AC/DC | 11 (Optional: 22)/150 | 11 (Optional: 22)/170 |

| Maximum engine power (boost mode) in kW (PS) | 250 (340) | 300 (408) |

| Maximum torque in Nm | 664 | 664 |

| Top speed in km/h | 200 | 200 |

| Acceleration from 0 to 100 km/h in s | 6.0 | 5.6 |

| Range in km (WLTP) up to | SUV 491 / Sportback 505 | SUV 582 / Sportback 600 |

| Unladen weight in kg (without driver) | 2,510 | 2,510 |

Audi SQ8 e-tron / Audi SQ8 Sportback e-tron: with its capacity of 106 kWh net (gross: 114 kWh), the battery powers three motors: one on the front axle, two on the rear axle, each driving one wheel, for a boost power of 370 kW and 973 Nm of torque. This results in acceleration from 0 to 100 km/h in 4.5 s and a top speed fixed of 210 km/h. The range of the S models is up to 458 km for the SUV and up to 471 km for the Sportback.

| Audi SQ8 e-tron |

|

| Battery energy in kWh net/gross | 106/114 |

| Maximum charging power in kW AC/DC | 11 (optional: 22)/170 |

| Maximum engine power (boost mode) in kW (PS) | 370 (503) |

| Maximum torque in Nm | 973 |

| Top speed in km/h | 210 |

| Acceleration from 0 to 100 km/h in s | 4.5 |

| Range in km (WLTP) up to | SUV 458 / Sportback 471 |

| Unladen weight in kg (without driver) | 2,650 |

Revised rear-axle motors in the Audi Q8 e-tron 50 and Q8 e-tron 55

The new Audi Q8 e-tron is equipped with electric motors on both axles that operate as asynchronous machines. The current flow in the stator windings creates a magnetic field around the axis of the rotor. A conceptual advantage of operating this way is that a permanent magnet is no longer needed in the electric motor. If there is no flow of current, the motors do not produce any drag losses and are therefore highly efficient. They also require little maintenance and are highly robust and comparatively light thanks to the aluminum rotor.

This engine concept was modified on the rear axle for the new Audi Q8 e-tron. Instead of 12, 14 windings now generate the electric magnetic field. The advantage to this is that the motor generates a stronger magnetic field at an identical current input, which in turn ensures higher engine torque. If it’s not fully expended, the electric motor thus requires less current to build up torque, reducing consumption and increasing range. We are shifting the engine characteristics at the same peak power to a more efficient place, taking real customer needs into account,” says Sami Robert Zaki, System Team Leader Drive at Audi. The boost function, which lets the driver access full system power at short notice by selecting S mode as well as on kickdown, ensures a more targeted focus on the speed ranges where a lot of power is needed for passing maneuvers. Based on several million kilometers of driving data, the developers have evaluated our customers’ usage behavior and responded by giving Audi e-tron drivers access to a predominant portion of its performance in the speed range up to 100 km/h. “The increase in efficiency is highly relevant for everyday driving,” says Zaki.

In normal driving conditions, the rear axle is the preferred drive axle for reasons of efficiency. The engine on the front axle is only used when customers require higher performance or if the driving situation calls for the quattro drive, for example on slippery roads or to stabilize the vehicle when taking curves. The drive of all four wheels can be adjusted manually by selecting the drive mode. If the driver switches from D to S, the Audi Q8 50 e-tron and Q8 55 e-tron run with permanent all-wheel drive. Whatever the driving mode, the Audi Q8 e-tron gives customers that typically Audi handling experience.

Audi drive select and four-stage ESC

The electric all-wheel drive builds on the intelligent networking of numerous control systems that ensure the typical quattro properties of high traction and driving stability. Important network elements include the four-stage electronic stabilization control (ESC) system and the power electronics, which interact to help balanced handling. Similarly, the control systems allow individual electronic intervention. In addition to normal mode, ESC offers a sport and an offroad mode, and the system can even be switched off entirely for higher performance in certain driving situations.

The characteristics of the Audi Q8 e-tron can also be adapted for driving on different terrains with the standard Audi drive select dynamic handling system. Whether relaxed travel, dynamic cornering, or off-roading, depending on the driving situation, road conditions, or personal preferences, customers can choose between seven profiles: auto, comfort, dynamic, efficiency, individual, allroad, and offroad.

Power electronics and the drive control unit: split-second reaction times

Each electric motor in the Q8 e-tron is powered and controlled by its own power electronics module, receiving data from the drive control unit (DCU), where all requests come together – from the accelerator pedal, the brakes, or the electric all-wheel drive. The power electronics modules read in sensor data 10,000 times per second and output current values for the electric motors. This results in the optimum use of output, during dynamic vehicle operation in particular. Some functions, such as vibration damping and the slip control functions, are integrated into the power electronics directly, enabling the deceleration-free transmission of interventions and improves, for example, the vehicle’s ability to accelerate on icy roads significantly. The two structurally identical power electronics modules are positioned on the housings of the electric motors and are integrated into the thermal management system of the drive system. They take up little space, and each weigh only eight kilograms thanks to their aluminum housing. The power electronics convert the direct current from the battery into three-phase current for the drive system. When the electric motors operate as a generator during recuperation, the power electronics convert the generated three-phase current into direct current and feeds it back to the battery.

Electric torque vectoring in the Audi SQ8 e-tron

The e-tron series’ S model marks the first time Audi has used three electric motors in a mass-produced model. This concept is continued in the SQ8 e-tron. The front axle is driven by an electric motor with a peak output of 124 kW. On the rear axle, there are two electric motors both with 98 kW of peak output that separately power a rear wheel. In boost mode, the front-axle motor produces up to 157 kW, and the two rear motors 138 kW each; this would amount to a total boost power of 433 kW, however, the value is limited to 370 kW by the battery. This means the SUV, which is just under five meters long, accelerates like a sports car from zero to 100 km/h in 4.5 seconds. In addition to acceleration, the drive concept shows its strengths on winding roads in particular; because the two rear electric motors are not connected in any way or coupled via a differential, apart from the shared cooling system, they can distribute the drive torque completely variably between the rear wheels.

Since there are no mechanical drives forces, only data and electric current, electric torque vectoring directs drive torque to the appropriate wheel in no more than five milliseconds. The latency, i.e., the time offset, is only around a fifth of that of a mechanical system – when cornering at high speed, the rear axle does not need to apply the brakes to keep the vehicle agile and stable.

When drivers accelerate out of curves dynamically, the outside rear wheel receives up to 220 Nm more than the inside one due to the gear ratio – the difference at the wheels is around 2,100 Nm. The yaw torque that is generated not only supports the self-steering behavior, but also requires a tighter steering angle to maintain the cornering radius.

At the dynamic limit, the unloaded front wheel on the inside of the curve is slowed down slightly – this small intervention, which would go unnoticed by the driver, prevents slippage and makes handling more agile and neutral. Traction is another advantage: if a rear wheel is on a road surface with low friction coefficient (e.g., a patch of ice or gravel) when accelerating, the torque can be distributed precisely and quickly between the two motors. The high-traction wheel receives almost the entire torque, while the low-traction wheel has practically none.

In normal everyday driving, when only a fraction of the available output is used, the electric motors on the rear axle drive the vehicle, increasing efficiency and range with no negative impact on the vehicle’s characteristics. When more output is used, the torque shifts to both axles so the SQ8 e-tron can immediately demonstrate its sporty character and take advantage of electric torque vectoring.

Intelligent braking and recuperation concept

In 90 percent of all braking situations, the Audi Q8 e-tron does not use its disk brakes, thanks to the intelligent recuperation concept. Up to a deceleration of 0.3 g, the system recuperates via the electric motors alone, without using the conventional brakes which then work as generators, converting the kinetic energy into electrical energy. Only when the driver uses the brake pedal to decelerate more than 0.3 g do the internally ventilated 18-inch wheel brakes come into play. Depending on the driving situation, the Audi Q8 e-tron decides whether to decelerate via the electric motor, the wheel brakes, or a combination of both – and does so individually for each axle. When braking from higher speeds, the system recuperates with around two-thirds of its drive power.

The optional paddles on the steering wheel can be used to select a total of three levels of regenerative braking. At the lowest level, the Audi Q8 e-tron glides without additional drag torque when the driver lifts off the accelerator, i.e., it glides freely and puts the input energy to the best possible physical use. No electricity flows to or from the electric motor while the vehicle is moving. In stage 1 (balanced – low deceleration) and 2 (strong – high deceleration), the electric motors develop a regenerative braking torque and produce electricity.

The car reduces the speed noticeably – the driver can decelerate and accelerate using just the accelerator pedal. In addition to manually adjusting the recuperation level with the steering wheel paddles, the driver can also select automatic mode in the MMI.

The predictive efficiency assist then regulates the deceleration as needed and predictively, for example in relation to the route or vehicles on the road ahead. Drivers can adapt the deceleration effect to the situation via the shift paddles; it remains active until the driver operates the accelerator pedal again.

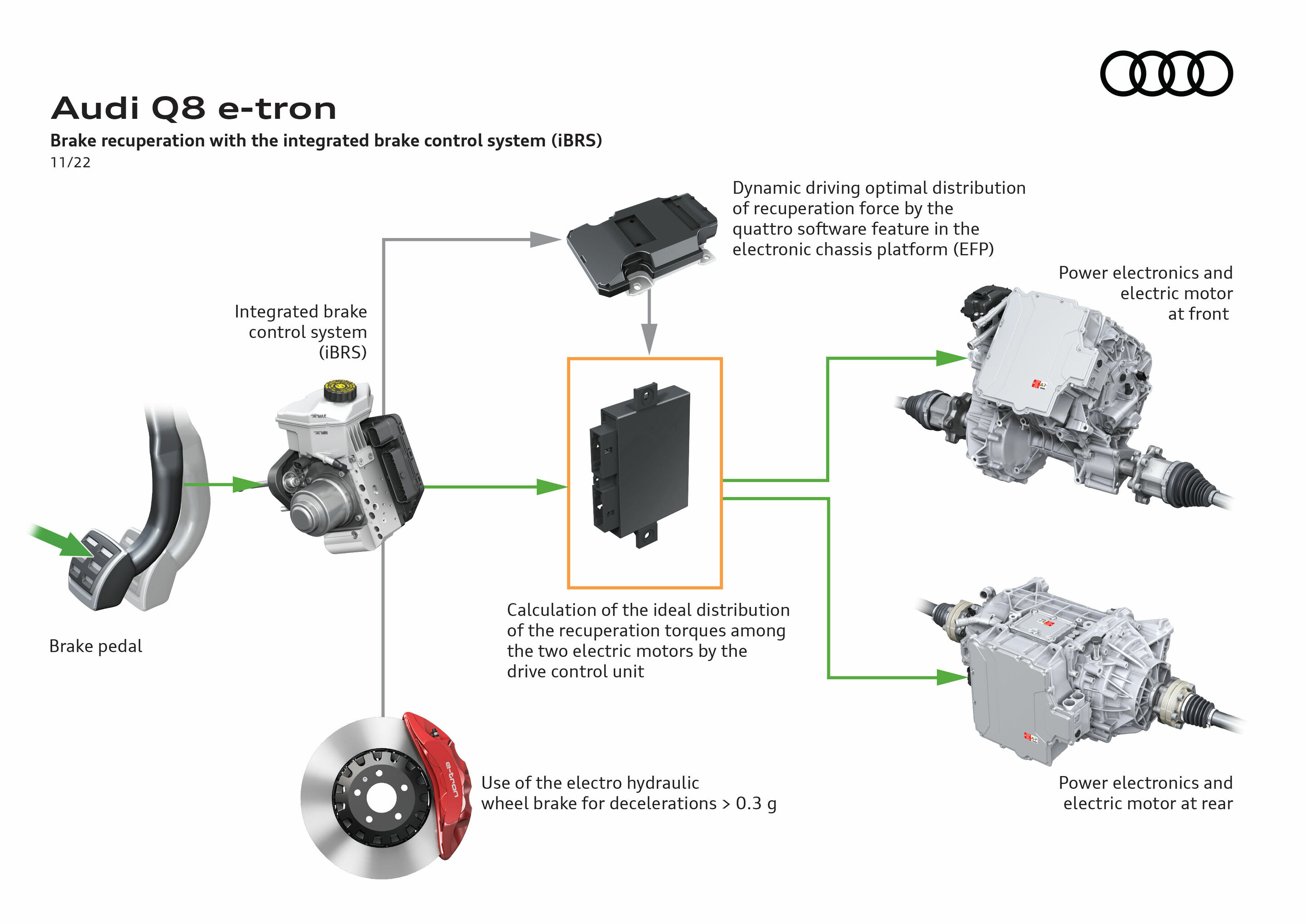

Electrohydraulically integrated brake system

The technical prerequisite for the efficient recuperation properties in the Audi Q8 e-tron is the brake-by-wire braking system – it completely decouples the brake pedal and brake hydraulics. When the driver presses the brake pedal, the system calculates whether the generators’ recuperation power is sufficient for the desired deceleration or whether it’s necessary to use the disc brakes on the front and rear axles. Audi was the first manufacturer in the world to use this electrohydraulically integrated brake control system in a mass-produced electric-drive vehicle, when it introduced the e-tron series.

If the situation demands a deceleration that exceeds 0.3 g, the controller computes the required amount of braking power within milliseconds. A displacement piston in the brake hydraulics generates additional pressure; put into motion by an electric spindle drive, it pushes brake fluid into the brake lines and generates additional brake force using the conventional friction brakes.

The transition between electric and hydraulic braking is smooth and homogeneous, the driver does not notice it – the brake forces remain constant. Using a pressure-resistant element, a second piston generates the familiar pedal feeling for the driver’s foot. In the case of ABS braking, the driver will not feel the pressure build-up and reduction in the pedal, otherwise felt as irritating, hard pulsations. Even at a very slow speed, such as during maneuvering, the Audi Q8 e-tron decelerates efficiently via the wheel brakes.

The new electrohydraulic actuation allows the brake control system to build up pressure for the wheel brakes with great precision, and roughly twice as fast as a conventional system. This enables a larger air gap, i.e., a greater distance between the brake pad and brake disk to be set, minimizing possible friction and heat generation and increasing the range. During automated emergency braking, there are only 150 milliseconds between when the brakes are applied and the presence of maximum brake pressure between the pads and disks.

Thanks to this rapid pressure build-up, the electrohydraulically integrated brake control system shortens the braking distance by up to 20 percent compared with a conventional brake system. Thanks to the recuperation output of the Audi Q8 e-tron, the wheel brakes are used less frequently in everyday driving, reducing wear and lowering service and operating costs for the vehicle.

To prevent the steel disks from rusting, a brake cleaning function automatically opts to use the friction brakes at certain intervals, even though recuperation would be possible, keeping the system in ideal operating condition.

A six-piston fixed caliper brake is mounted on the front axle, and a single-piston floating caliper on the rear axle. The internally ventilated discs measure 375 mm in diameter at the front and 350 mm at the rear.

All terms marked in the text are explained in detail in the technology lexicon at www.audi-mediacenter.com/en/technology-lexicon. The equipment, data and prices specified in this document refer to the model range offered in Germany. Subject to change without notice; errors and omissions excepted.