Pilot Project: Physical Recycling Makes Mixed Plastic Waste Recyclable

- Audi is setting up cycles as an integral part of its automotive value chain

- Test phase launched: physical recycling complements research projects on chemical and mechanical plastic recycling from old vehicles

- The vision: create high-quality granulate materials for use in serial automotive manufacturing

Audi is promoting sustainable product development and wants to establish more and more cycles. Together with partners from science and industry, the company with the four rings is researching ways of improving material recyclability and saving primary materials. In collaboration with the Fraunhofer Institute, the manufacturer is now testing an additional method of recycling plastics and making them usable for mass production. As part of Audi Environmental Week, Audi employees will be focusing on recycling and many other ideas for a more sustainable company. This is the campaign’s second year and it is intended to promote networking, exchange, and interdisciplinary cooperation with the aim of improving Audi’s sustainability performance.

Audi wants to make cycles an integral part of the automotive value chain. The company is launching pilot reprocessing projects for a growing number of materials and components. The objective is to gain experience with as many processing techniques as possible and produce derivatives for future application of particular raw materials. Material cycles have several advantages: on the one hand, they reduce demand for renewable and raw nonrenewable materials. On the other hand, materials based on material cycles have a more favorable energy footprint. The company with the four rings is also keeping a close eye on the energy required for recycling – anything that does not make sense from an ecological point of view will not be pursued after the pilot phase. In addition, ever more efficient recycling methods are increasing the company’s sustainability as a whole.

Different Recycling Methods for Different Types of Plastic

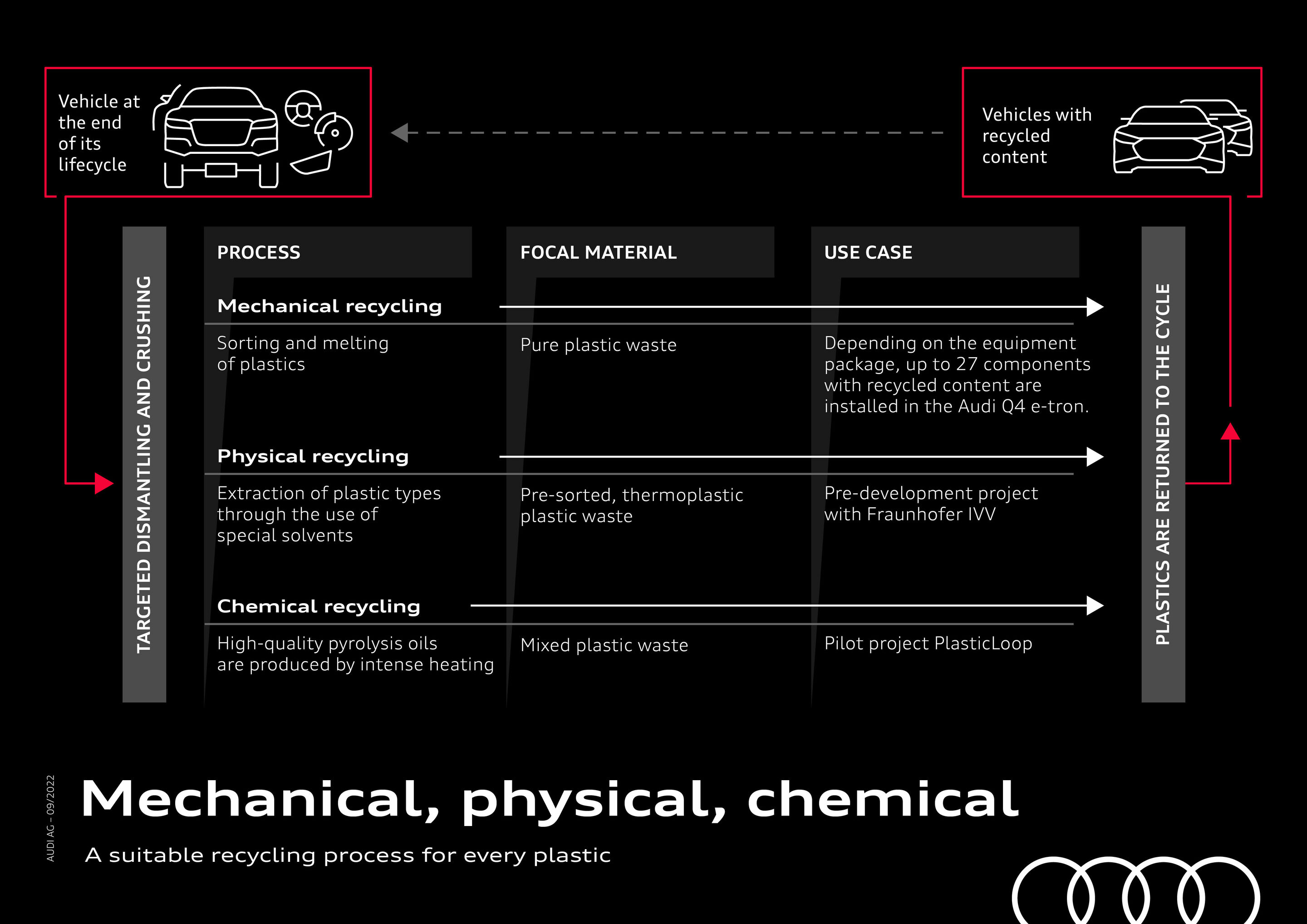

Since not all types of plastic can be sorted and recycled with the same quality or even in the same way, Audi is looking at different technologies at the same time: mechanical, chemical and, most recently, physical recycling. Audi’s vision is to qualify more and more materials for diverse and demanding applications in cars and to identify optimal processing and recycling techniques in order to be able to close cycles. “Our focus is always on getting as many plastic contents as possible out of the car at the end of its life in order to be able to recycle them again,” says Mike Herbig of Audi’s polymer team.

Today’s vehicles typically contain more than 200 kilograms (440 lbs.) of various plastics and plastic composites. Bumpers, radiator grilles, various interior parts, as well as components in the drive system and air conditioning are all made from it. This sometimes mixed plastic waste is first mechanically crushed and separated from other materials. It can then be processed again into plastic granules in a subsequent process.

Same Requirements for Components Made from Recycled Materials and Virgin Materials

The quality demands placed on the plastics are high. The same criteria apply to recycled components as to virgin materials. These include crash safety, heat resistance, and media resistance, e.g., against organic solvents, oil, or hydraulic fluids. In addition, there is dimensional stability and quality, feel, appearance, and smell throughout the vehicle’s entire service life. Environmental requirements also must increasingly be taken into account. Mike Herbig says, “We only use a recycled material if the components made from it also meet the requirements, which is to say if the quality of the parts remains the same over their entire useful life.”

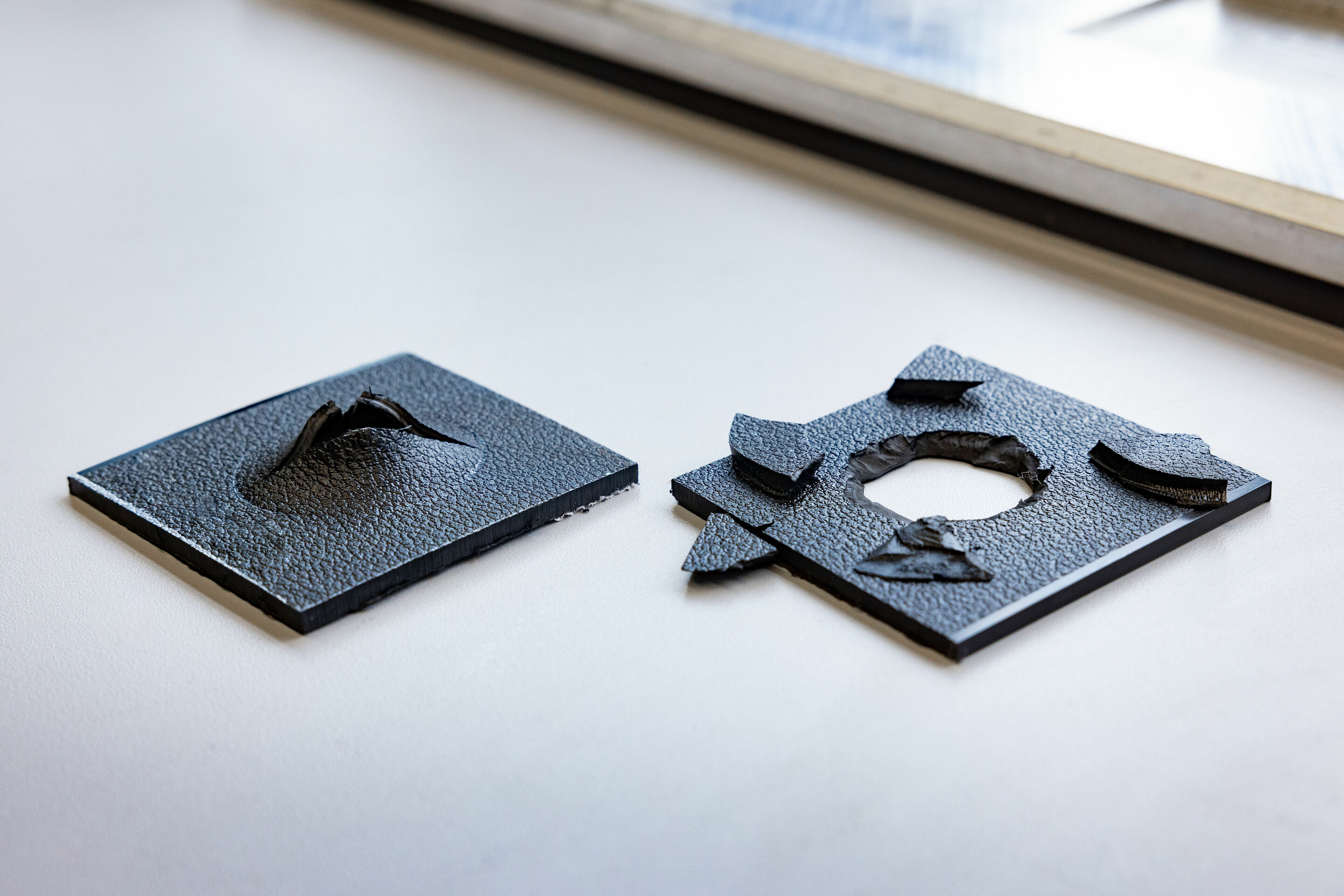

Mechanical recycling of plastics reaches its limits where different plastics are processed as a composite and various adhesives, coatings, and fillers such as glass fibers are used. An added disadvantage is that the quality of the plastics decreases with each mechanical processing step. As a rule, plastics recycled in this way are no longer suitable for use in vehicle construction, especially not for safety-related components.

Together with the Karlsruhe Institute of Technology (KIT) and industry partners, Audi has also developed on a chemical recycling method. Mixed plastic waste is processed into pyrolysis oil. Pyrolysis oil can replace crude oil as a raw material in the production of high-quality plastics. The components produced in this way are just as valuable and safe as when they are made from virgin material.

Physical Recycling Feasibility Study

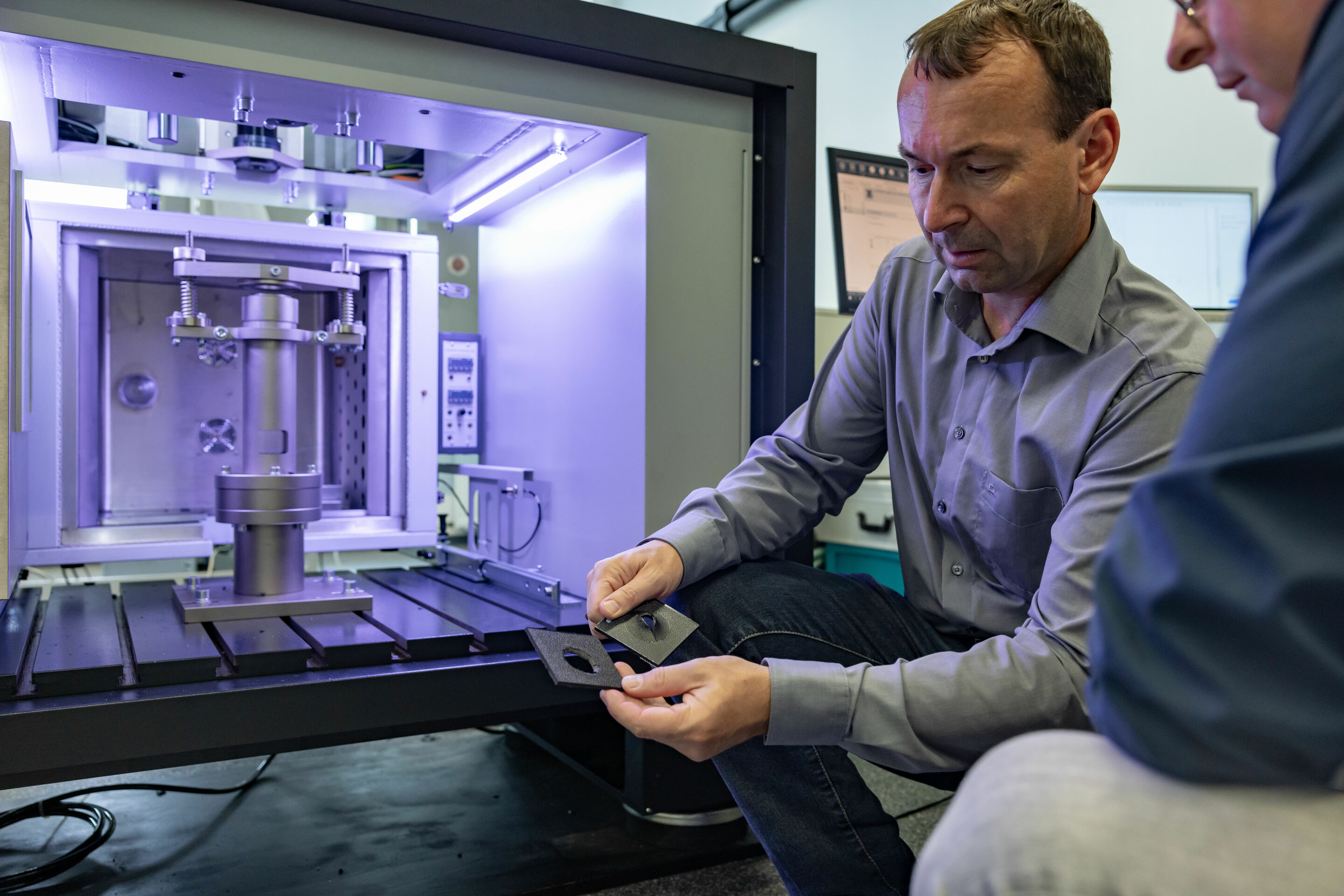

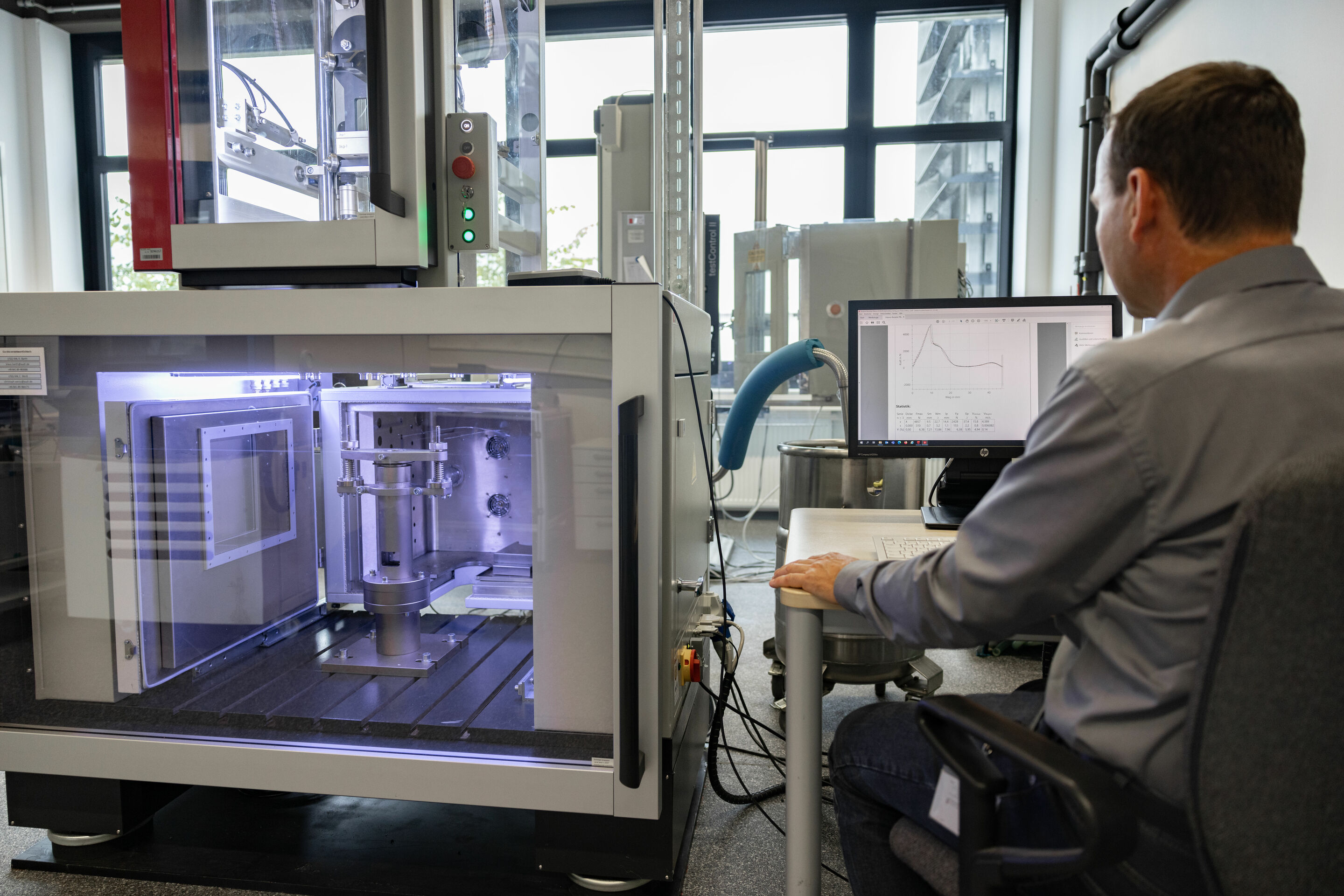

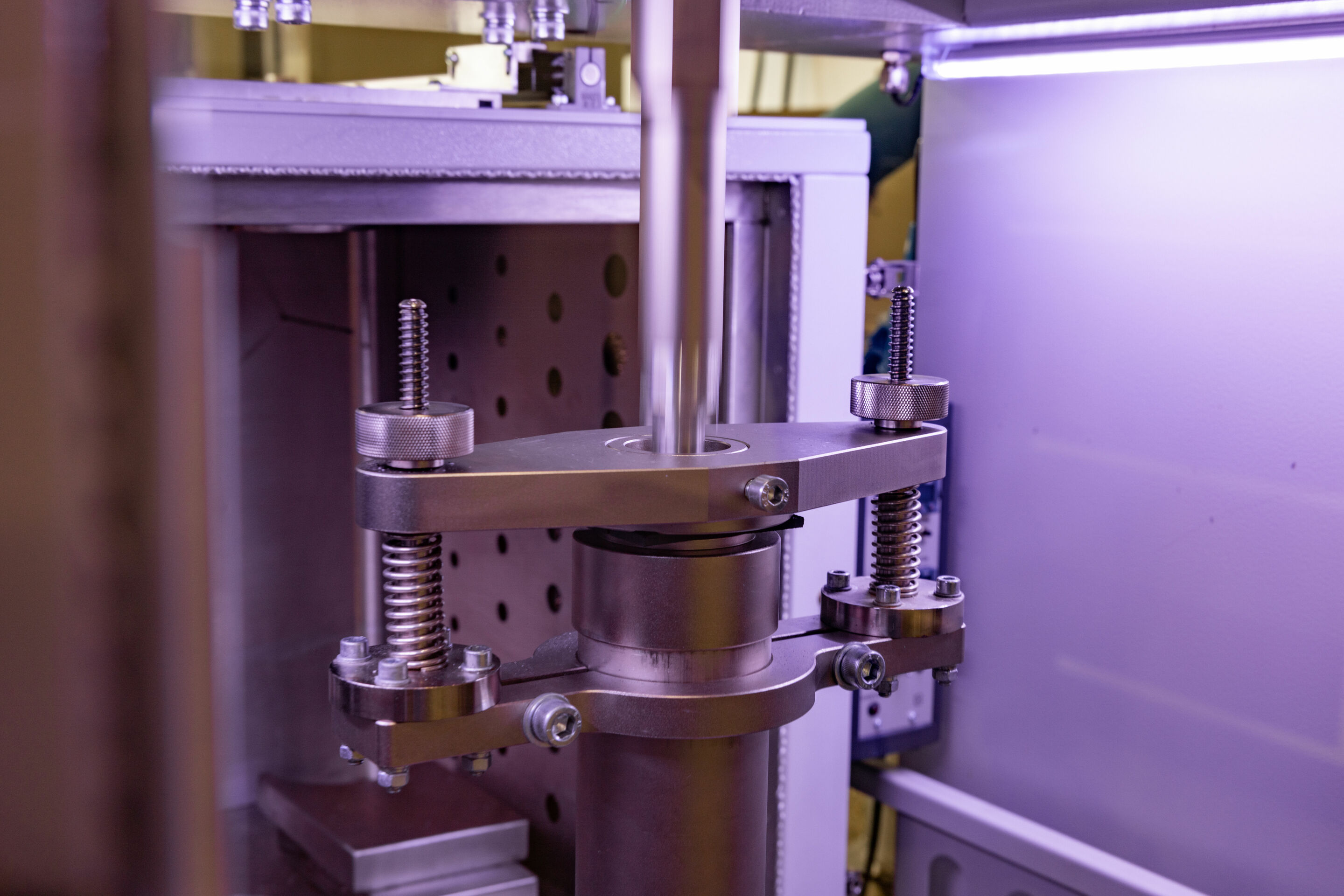

In addition to research projects focusing on mechanical and chemical recycling, Audi is also conducting a feasibility study in cooperation with the Fraunhofer Institute for Process Engineering and Packaging IVV to investigate the possibilities of the physical recycling of automotive plastic waste and its reuse in vehicles. This method makes it possible to work with plastics with significantly higher levels of contamination, meaning that simple and incomplete pre-sorting from on old vehicle is sufficient.

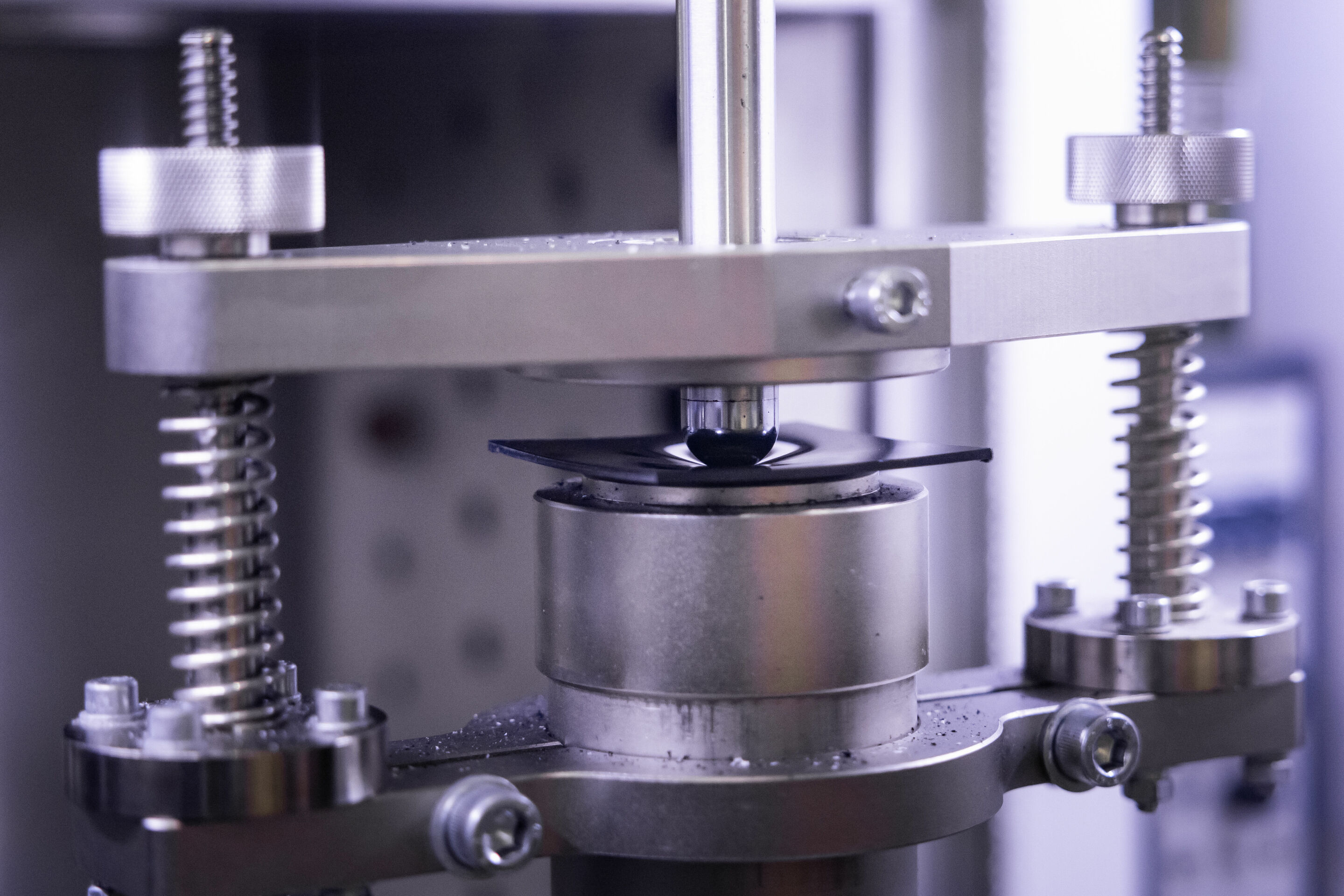

Unlike chemical recycling, plastic is not destroyed by physical recycling. Instead, it is dissolved with solvents. This means that no chemical degradation reaction takes place and the polymer chains remain undamaged. “Only substances that are absolutely harmless are used as solvents,” explains Dr. Martin Schlummer of Fraunhofer IVV. “Other solids that could interfere with the new end product are separated”. Dissolved substances such as flame retardants can also be dissolved from the plastic solution if necessary. The solvents used are then evaporated and also fed into the cycle. After drying, this results in a very pure plastic granulate that matches the quality of virgin material.

The aim is now to produce larger quantities of this granulate in order to ensure its technical feasibility and to test its cost-effectiveness. In further testing, the “plastic with a past” will be transformed into add-on parts, such as the seat height adjuster. It is a small component, but it has to meet high standards in terms of emissions and odor. In the future, Audi plans to use the various recycling technologies to complement each other in order to recover plastics from old vehicles for high-quality reuse.

Further Increase in the Proportion of Recycled Materials in the Vehicle

In the future, Audi wants to increase the proportion of recycled materials in vehicles further. There are already as many as 27 components made with recyclates in an Audi Q4 e-tron. The exterior includes components such as the mounting bracket, a component that has to meet particularly high demands in terms of its mechanical properties. What’s more, large proportions of the headlight mounts, wheel arch liners, fender covers, floor trim, and wheel spoilers are made from secondary raw materials.

In the interior of the Audi Q4 e-tron, recyclates are used in the insulation and damping materials. Moreover, many of the visible surfaces contain recycled materials. These include the floor covering and parts of the luggage compartment trim. In the S line interior, the upholstery for the sport seats is made of Dinamica microfiber material, in combination with artificial leather. Polyester fibers make up 45 percent of the Dinamica material, which nonetheless looks and feels like suede. The fibers used are derived from recycled PET bottles, old textiles, or residual fibers.

Audi Environmental Week Promotes Interdisciplinary Exchange

Audi is hosting Environmental Week for the second time: the interactive format promotes the transfer of knowledge and is intended to encourage people to challenge their own behavior. This Environmental Week will feature more than 50 presentations by employees for employees and expert discussions on environmental protection, recycling, CO2 reduction, water conservation, and nutrition, combined with playful challenges and activities to join. Rüdiger Recknagel, Head of Environmental Protection, says that “the motto of Environmental Week is ‘Make it your mission – always.’ Sustainability is our priority.”