Over 40 years of quattro – over 40 years of Vorsprung durch Technik

Back to overview40 years of quattro: the highly successful technology from Audi

A technological success story from Audi: the quattro drive system is already over 40 years old. Since the original quattro first made its debut in 1980, the principle of four-wheel drive has become one of the cornerstones of the brand. To date Audi has sold almost 11.2 million cars with quattro drive. The most recent chapter of the success story is electric: The Audi e-tron* uses electric all-wheel drive, and the e-tron S* models already feature its first expansion stage: electric torque vectoring, i.e. the need-based shifting of torque between the rear wheels.

The track record

“quattro” means “Audi,” and “Audi” often means “quattro.” Now, 40 years after the original quattro first appeared, the brand with the four rings has notched up some impressive figures. Through 2020, Audi had produced 11,199,144 cars with all-wheel drive. Some 45.31 percent had all-wheel drive in 2020.

The quattro drive system has been one of the biggest cornerstones of the Audi brand for 40 years. It is represented in every model series except the compact A1. All larger models – the A8, the Q7, the Q8, the e-tron*, and the e-tron Sportback*, the R8 and all S and RS models transfer their horsepower to the road through four wheels as standard. Audi currently has 16 quattro models in its portfolio on the German market.

The mechanical quattro systems

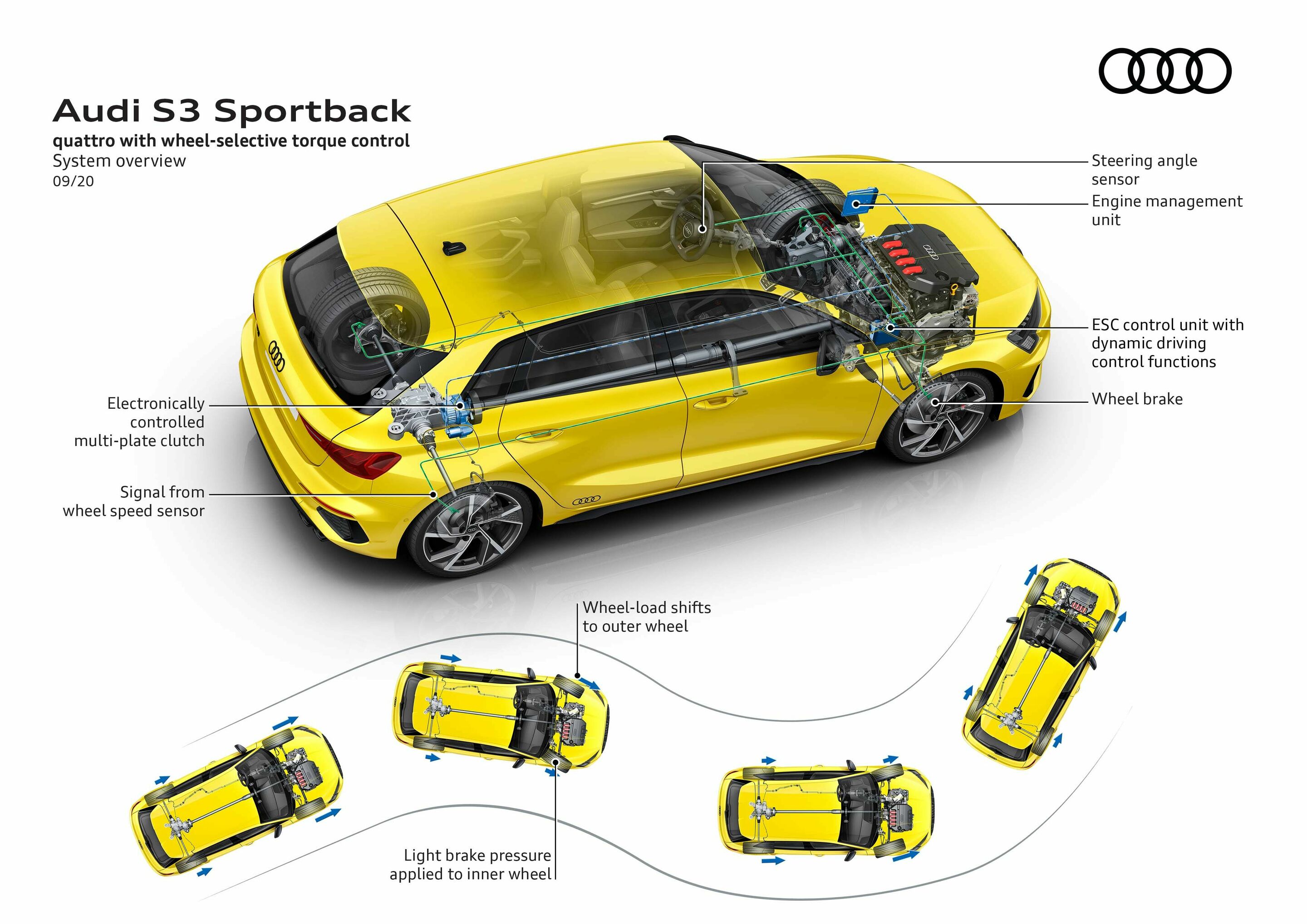

Throughout its model range, Audi offers a very wide variety of car concepts – and quattro technology is equally multifaceted. One thing that all versions share is a supplementary solution: Wheel-selective torque control is a software function of Electronic Stabilization Control (ESC). During dynamic cornering, it applies the brakes very gently to the unloaded wheels on the inside of the curve before they have the chance to slip. Due to the difference in propulsion forces, the car turns slightly into the corner. This input makes the handling even more neutral, dynamic, and stable.

Two systems: quattro drive for longitudinal engines

The Audi models with longitudinal front-mounted engines and tiptronic automatic transmissions employ the classic quattro drive system with a self-locking center differential, which operates by purely mechanical means and therefore without any delay whatsoever. It is configured as a planetary gear. This involves an internal gear encompassing a sun gear, with cylindrical planet gears, joined to the rotating housing, turning between them.

In regular driving operation, 60% of the drive torque flows to the rear axle via the internal gear, which has a larger diameter, and its associated output shaft. The remaining 40% goes to the front axle via the smaller sun gear. This asymmetric, dynamic torque distribution results in sporty, rear-biased basic handling. If the wheels on one axis lose traction, the geometry of the gearwheels and helical gearing in the differential produce axial forces. These forces act on friction discs to produce a locking effect that diverts the bulk of the drive torque to the wheels with the better traction. Up to 70% can be directed to the front wheels and up to 85% to the rear.

The quattro with ultra technology optimized for efficiency is designed for Audi models featuring a longitudinal front-mounted engine working with a manual transmission or the S tronic dual-clutch transmission. During moderate driving, quattro with ultra technology enjoys all the advantages of front-wheel drive. All-wheel drive remains continuously available however, and is there immediately when needed.

The control system for the quattro powertrain is comprehensively networked. It acquires and evaluates data – in ten millisecond cycles – such as the steering angle, transverse and longitudinal acceleration and engine torque. As a result, all-wheel drive is generally activated predictively, i.e. in anticipation of the need for it. When cornering at speed, the control unit detects roughly half a second in advance when the wheel on the inside of the curve will reach the traction limit and quickly sends drive torque to the rear wheels. There are no differences in terms of traction and handling compared with conventional permanent quattro drive systems.

The concept with two clutches in the drivetrain gives quattro with ultra technology a significant efficiency advantage of on average roughly 0.3 liters of fuel per 100 kilometers (62.1 mi) over the competition. When the system changes to front-wheel drive, the front clutch – a multi-plate clutch at the transmission output – disconnects the propshaft. A decoupling clutch also opens in the rear differential. It shuts down the rotating components that cause the most drag losses here, such as the large crown wheel running in the oil bath.

Mechanical torque vectoring at the rear axle: sport differential

The sport differential is available for the particularly powerful and sporty Audi models with tiptronic. It further improves handling, traction, and stability by distributing drive torque ideally between the rear left and right wheels in all operating states. During turning or acceleration, mechanical torque vectoring literally presses the car into the curve without producing any understeer.

In addition to the functions covered by a conventional differential, the sport differential has a transmission stage and hydraulic multi-plate clutch fed by an oil pump. During fast cornering, the clutch engages for the wheel on the outside of the curve, which has better grip due to the dynamic wheel load distribution. The clutch variably imposes a higher speed on the transmission stage for the relevant wheel. The extra torque required is taken from the opposite wheel via the differential, which means that almost all the torque goes to the wheel on the outside of the curve. Up to 1,200 Nm (885.1 lb-ft) of drive torque can be transferred to one wheel in this way.

Hydraulic multi-plate clutch: the quattro drive for transverse engines and the Audi R8

The compact models with transverse engine configurations use a quattro drivetrain centered on an electronically controlled hydraulic multi-plate clutch. It is mounted at the end of the propshaft before the rear differential to optimize weight distribution. Inside it is a package of metal friction rings mounted in alternating order one behind the other. Half of these plates are meshed with the clutch drum, which rotates with the propshaft. The other half is connected with the rear axle differential via a short shaft.

The all-wheel drive control constantly calculates the best torque distribution between the front and rear axles based on numerous data. When the requirements change, the electric axial-piston pump in the clutch builds up as much as 40 bar of hydraulic pressure within just a few milliseconds. It presses the friction plates together, which enables variable transmission of the drive torque from the front axle to the rear. The stronger the pressure, the more torque is directed to the rear axle – up to 100 percent when the clutch is fully closed.

On the especially sporty models with transverse engine layouts, clutch management is designed to focus on dynamics, with more frequent and pronounced rearward torque distribution. The clutch can already transmit part of the torque to the rear when the driver turns the steering wheel with a sporty driving style. This effect assists greatly with the handling. During load changes, the distribution of torque allows precise turning into the bend, which further increases driving dynamics.

The Audi S3* and the revised Q2 use a multi-plate clutch of the latest generation whose control is integrated in the modular dynamic handling control. This new system collects data from all components that are relevant for transverse dynamics and manages the quick and precise interplay between them. When the car is driven with a more restrained style, the clutch can be disengaged entirely to boost efficiency. The new multi-plate clutch is around one kilogram (2.2 lb) lighter than its predecessor part while offering increased efficiency thanks to various details such as bearings and oil supply.

In second-generation versions of the R8 high-performance sports car (since 2015), Audi has fitted the electrohydraulic multi-plate clutch in a special drive layout. Behind the V10 mid-mounted engine is a compact seven-speed S tronic along with a locking differential to drive the rear wheels. One of its output shafts is linked to the propshaft that runs to the front-axle drive. It holds the water-cooled multi-plate clutch, which distributes the necessary torque to the front wheels in any driving situation. There is no fixed basic distribution; in extreme cases, up to 100% can be transmitted to the front or rear axle here, too.

quattro 2.0: electric all-wheel drive and electric torque vectoring

With the Audi e-tron and the e-tron Sportback, the brand with the four rings is making strides into the sustainable future of transportation – and the future of the quattro drive system. The two electric motors on the front and rear axles enable electric all-wheel drive that ensures the best possible traction and sporty handling. The Audi e-tron S uses electric all-wheel drive, which integrates and reinterprets the strengths of the sport differential.

Audi e-tron* and Audi e-tron Sportback*: Electric all-wheel drive

Electric all-wheel drive regulates the ideal distribution of torque to both axles permanently and fully variably, combining the efficiency of a single-axle drive with the handling and traction of an all-wheel drive. When driven at a calm pace, the Audi e-tron and e-tron Sportback use only the rear electric motor for propulsion.

If the driver demands more power than it can supply, the control units will activate the motor on the front axle. This happens predictively in many situations, even before slip occurs in icy conditions or during fast cornering, or if the car understeers or oversteers. It takes just roughly 30 milliseconds from the system detecting the situation to the drive torque for the electric motors kicking in. In combination with wheel-selective torque control, electric all-wheel drive offers excellent traction, outstanding stability, and plenty of fun whatever the weather. To a great extent, the driver can adjust the character of the handling via the suspension control systems, from supremely stable to sporty.

In the Audi e-tron S and e-tron S Sportback, Audi is presenting the latest generation of electric all-wheel drive. Each of the two exceptionally dynamic electric SUVs comes with three electric motors on board, allowing drivers to experience the benefits of the classic sport differential on the rear axle. Each of the two rear electric motors actuates one rear wheel directly via its transmission. As with the axles, there is no mechanical link. Electric torque vectoring, that is the distribution of torque between the rear wheels, is performed in a matter of milliseconds, and it is possible to engage extremely high torque.

If the car turns into a curve quickly, the electric motor will direct extra torque to the rear wheel on the outside of the curve, while the brakes will be applied to the inside rear wheel accordingly. The difference can amount to as much as 220 Nm (162.3 lb-ft), which translates to around 2,100 Nm (1,548.9 lb-ft) at the wheels as a result of the gear ratios. These values are higher as compared to a mechanical system. In addition, the latency, that is the time offset, is four times shorter.

All control units involved in electric all-wheel drive and the electric sport differential work closely together, which is what makes the high speed and precision of the control operations possible in the first place. Electronic Stabilization Control (ESC), the drive control unit (DCU), the electronic chassis platform (ECP), and the power electronics control units all have roles to play.

Audi RS 3*: quattro drive system with electrically controlled multi-plate clutch

For the first time in an Audi, the torque splitter is being used in the new Audi RS 3*: it enables active, fully variable torque distribution between the rear wheels. Unlike the rear axle differential and the existing multi-plate clutch package on the rear axle, the torque splitter uses an electronically controlled multi-plate clutch on each drive shaft.

For sportier driving, it increases the torque on the rear wheel on the outside of the curve, which significantly reduces the tendency toward understeering. When driving on closed roads, the torque splitter enables controlled drifts.

One step ahead of the competition: the technical milestones

quattro technology can trace its roots back to the winter of 1976/77, when a team of Audi engineers conducted a series of test drives in the deep snow of Sweden. An Iltis traveled along for comparison purposes, and the all-terrain military vehicle with its high ground clearance outperformed the much more powerful front-wheel-drive prototypes. During this trip, it dawned on the engineers that Audi could realistically use the all-wheel drive system even on high-performance passenger cars – but it would have to be a completely new type that was lightweight, compact, and efficient, and could manage without a heavy transfer case or second propshaft.

The stroke of genius that made it all possible was the hollow shaft – a drilled-out, 263 millimeter (10.4 in) secondary shaft in the transmission that directed power in two directions. From its rear end, it drove the housing of the center differential, which was configured as a manually locking bevel-gear differential. In normal situations, it sent 50% of the power along the propshaft to the rear axle, which was equipped with a second locking differential. The other half of the torque was transferred to the front axle’s differential along an output shaft rotating inside the secondary shaft. The quattro drive system was born. The center differential has evolved continuously since then.

Since 1980: quattro technology for longitudinal engines

The new technology made its first appearance at the Geneva Motor Show in 1980, fitted to the Audi quattro, an angular coupé with a five-cylinder turbocharged engine delivering 147 kW (200 PS). Originally planned for only low-volume production, the original quattro ended up remaining part of the model line-up until 1991, having undergone numerous refinements along the way. In 1984, it was joined by the Audi Sport quattro with a short wheelbase. Producing 225 kW (306 PS), it was an exclusive high-performance sports car at the time.

With the new Audi 80 released in 1986, the brand introduced the second generation of its quattro technology, featuring the Torsen differential (Torsen: torque sensing), which was designed as a worm gear transmission. The new differential was accompanied by an enormous technological advance and provided a technical basis that has undergone extensive further development and is still used today. When a vehicle axle lost traction, friction would be created in the helical gears of the differential, allowing up to 75% of the torque to be diverted to the other axle. These higher locking figures enabled a clearly defined torque distribution in every driving situation.

The next big step in the evolution of the models with longitudinal front-mounted engines came in 2005 with the Audi RS 4. The new planetary gearing distributed the forces in a rear-biased 40:60 ratio in normal conditions. This third generation of the center differential has undergone further stages of development since then. The current generation can distribute 85% of the drive torque to the rear axle and up to 70% to the front axle as needed.

1999 onward: new developments across all technical platforms

Audi has continued to expand its range of quattro models over the course of 40 years. The decision was made back in the early 1980s to offer the quattro drive system across the board. The new models helped to pave the brand’s way into the premium segment. The first TDI with permanent all-wheel drive appeared in 1995; four years later, the technology moved into the compact class. The A3 and the new TT featured the electronically controlled hydraulic multi-plate clutch.

The first generation of the Audi R8 high-performance sports car launched in 2007. Its quattro drive system was a very special development, with the transmission in the rear integrating a power take-off supplying an unregulated viscous coupling on the front axle via a propshaft. It could divert 15% to 30% of torque to the front wheels when conditions called for it. In the second-generation version of the R8 (2015), the viscous clutch was replaced with a controlled multi-plate clutch.

The sport differential for the powerful A and Q models came in 2008, making its debut in the Audi S4. Finally, the quattro system with ultra technology optimized for efficiency joined the technology line-up when it arrived in the Audi A4 in 2016. As the most recent major innovation in the mechanical quattro world to date, it solved the conflict of objectives between dynamic handling and efficiency. With the electric all-wheel drive and electric torque vectoring, Audi opened up a completely new chapter in technology history in the e-tron family in 2019.

quattro in motorsports

Audi entered the world of rallying as a works team in 1978, initially running front-wheel drive cars. Barely a year had passed since the original quattro was first unveiled in Geneva than the brand began to achieve enormous success in the World Rally Championship. Hannu Mikkola of Finland won the first six special trials in the snow at the 1981 Monte Carlo Rally. He had a lead of almost six minutes when victory slipped through his fingers due to a minor accident. He recorded his first victory at the next round in Sweden.

1982–1987: supremacy on gravel

The following year, the quattro dominated the championship. Audi set a new benchmark with seven victories and easily won the manufacturers’ championship. One year later, Mikkola took home the drivers’ title. The 1984 season also started off with a bang – the newly recruited two-time world champion Walter Röhrl won the Monte Carlo Rally ahead of his teammates Stig Blomqvist (Sweden) and Mikkola. At the end of the season, Audi claimed both the manufacturers’ title and the drivers’ title with Blomqvist.

To make better use of the loose regulations of the Group B class of rallying, Audi developed the Sport quattro for the 1984 season. This had a shorter wheelbase that promised nimbler handling. It was followed in 1985 by the Sport quattro S1, which developed 350 kW (476 PS) and was instantly elevated to legendary status due in part to its striking rear spoiler. In the middle ratio, the 1,090-kilogram (2,403.0 lb) S1 shot from 0 to 100 km/h (62.1 mph) in 3.1 seconds. In the last event of the season, the British RAC Rally, Walter Röhrl used a dual-clutch transmission that was actuated pneumatically – a precursor to today’s S tronic.

When the exhilarating Group B years came to an end in 1986, Audi pulled out of the World Rally Championship – but not without one last bombshell. In July 1987, Röhrl triumphed at the Pikes Peak hill climb, driving an extensively modified Sport quattro S1 adorned with some enormous wings. Michèle Mouton (France) and Bobby Unser (USA) had already won the classic race in the US State of Colorado in the two previous years. Walter Röhrl tackled the 19.99-kilometer (12.4 mi) course, very little of which was paved at the time, in a record time of 10 minutes and 47.85 seconds, hitting a top speed of 196 km/h (121.8 mph). As he noted, “It was the very pinnacle of what can be done with a rally car.”

1988–1992: success in touring car racing

The brand competed in the Trans-Am series in the USA with the Audi 200 in 1988, winning the manufacturers’ and drivers’ titles at the first attempt, the latter courtesy of US driver Hurley Haywood. Haywood and Hans-Joachim Stuck scored seven wins out of 15 races in the IMSA GTO series in 1989, when the regulations were a little more relaxed. The five-cylinder turbo in their Audi 90 quattro hit top form at around 530 kW (720 PS).

Audi switched to the Deutsche Tourenwagenmeisterschaft (DTM) touring car championship in 1990. Stuck won the drivers’ title with the big and powerful V8 quattro that first year, followed by Frank Biela in 1991. By the time Audi withdrew from the series in 1992, it had won 18 out of 36 races. In 1996, the Audi A4 quattro Supertouring, with its two-liter, four-cylinder engine, entered seven national championships on three continents – and won them all. Because of its supremacy, the European rules largely banished all-wheel drive from touring car competition two years later. The quattro’s record up to that point read as follows: four titles in the World Rally Championship, three victories at Pikes Peak, a championship win in the Trans-Am, two DTM titles, eleven national touring car championships and a World Touring Car Cup.

2012–2014: three overall victories at Le Mans

It wasn’t until 2012 that an Audi all-wheel drive race car – the Audi R18 e-tron quattro with hybrid drive – once again took to the track for a circuit race. A V6 TDI drove the rear wheels, while a flywheel accumulator supplied recuperated energy to two electric motors on the front axle. When the situation called for maximum traction during acceleration, the racing car was capable of throwing its temporary quattro drive system into the mix for a few crucial seconds. With three consecutive overall victories at the 24 Hours of Le Mans and two drivers’ and manufacturers’ titles in the World Endurance Championship (WEC), Audi provided a convincing demonstration of the potential of the concept.

The enduring appeal of quattro

quattro is an icon. The name represents safe driving and sportiness, technical expertise and competitive superiority. The success of quattro models on the road and in racing has laid the foundation for this, while a series of legendary TV commercials has served only to underline it.

One unforgettable moment is the clip from 1986 filmed at the Kaipola ski jump in Finland, featuring the red Audi 100 CS quattro with professional rally driver Harald Demuth at the wheel scaling the 37.5-degree incline under its own power. In 2005, Audi repeated this feat on the same ski jump, which was restored specially for the event, with an S6. Circuit and rallycross champion Mattias Ekström (Sweden) performed a similar feat in 2019. He tackled the steepest section of the Streif ski course at Kitzbühel in an Audi e-tron quattro* with three electric motors, negotiating gradients of as much as 85%.

Audi has fueled the appeal of quattro again and again over 40 years with a succession of spectacular concept cars. The quattro Spyder, presented at the 1991 International Motor Show (IAA) in Frankfurt am Main, Germany, was the brand’s first thoroughbred sports car of the post-war era and its first aluminum-bodied car. Just a few weeks later, Audi presented the Avus quattro at the Tokyo Motor Show. It was designed to feature a W12 engine producing 374 kW (509 PS) mounted longitudinally ahead of the rear axle, the manual transmission in the quattro drivetrain positioned between the front wheels.

The Audi TT quattro Coupé and Roadster concepts presented in fall 1995 indicated the way to series production. Three more concept cars marked the expansion of the model range in 2003. At the Detroit Motor Show in January, Audi presented its Pikes Peak quattro, the predecessor to the Q7. This was followed at the Geneva Motor Show by the Nuvolari quattro two-door coupé, which paved the way for the A5. Then, in September, the Audi Le Mans quattro was the star of the IAA in Frankfurt – and also the spitting image of what would later become the R8.

The Audi R8 e-tron concept, one of the stars of the IAA in 2009, was a sports car with electric-only drives at all four wheels. In 2010, the Audi quattro concept – a re-interpretation of the original quattro – appeared at the Paris Motor Show. From 2015 on, numerous concept cars heralded the future arrival of standard e-tron models with electric all-wheel drive: the Audi e-tron quattro concept (IAA 2015), the Audi e-tron Sportback concept (Shanghai 2017), the Audi e-tron GT concept (Los Angeles 2018), and the Audi Q4 e-tron concept (Geneva 2019).