History

Back to overviewThe name Automobili Lamborghini stands for exclusive and emotional super sports cars. After an eventful history, a new era is evolving with the company’s electrification strategy.

Over the last 60 years, Automobili Lamborghini has developed a series of impactful and coveted cars. During this time, its headquarters have been upgraded, expanded, and reconfigured in line with production, environmental, and technological needs, but it has never lost its original core structure.

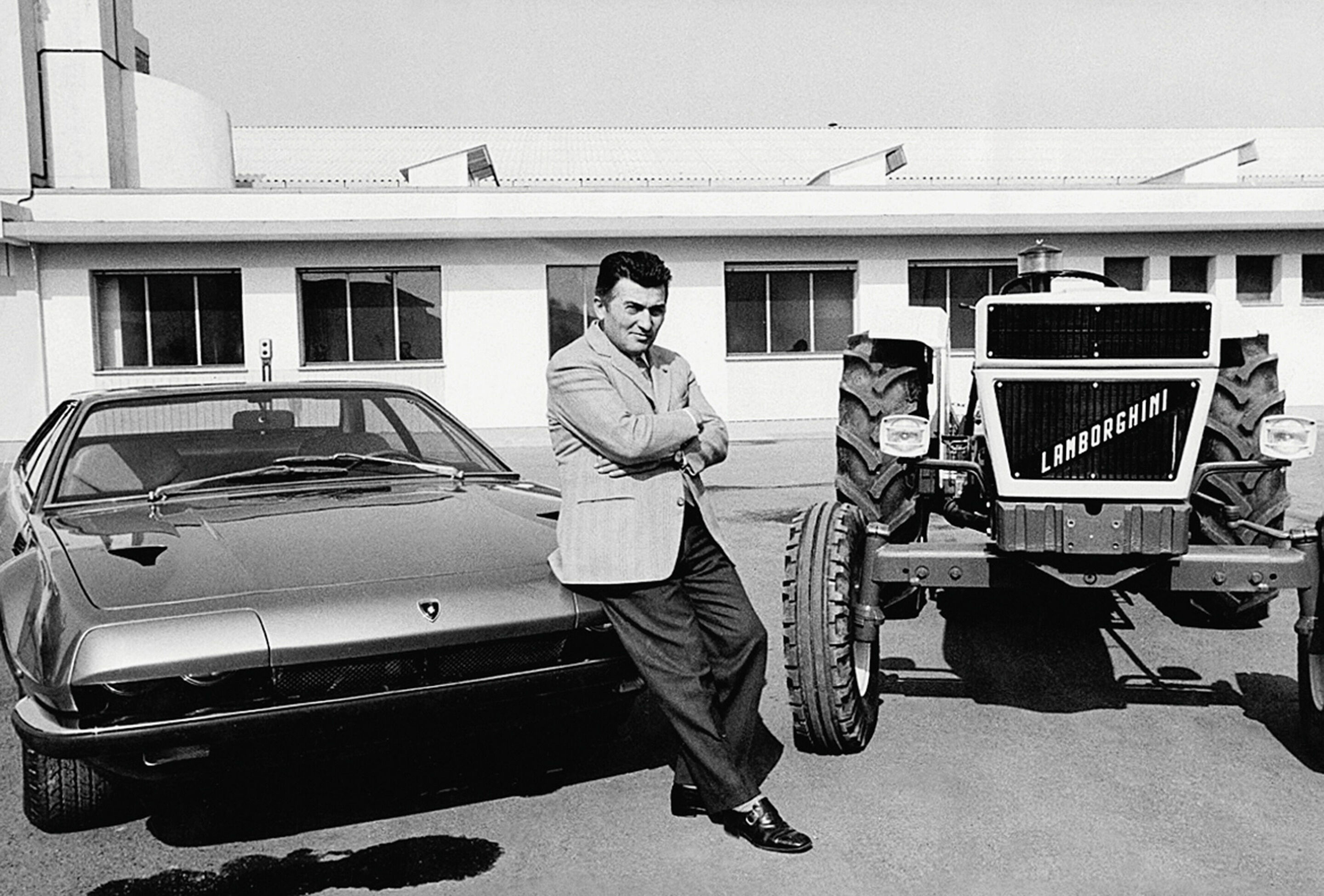

In 1963, Ferruccio Lamborghini chose to build his new factory in Sant’Agata Bolognese, just a few kilometers from his hometown of Cento. Construction of the initial part of the factory, which was considered one of the most modern of its time, progressed very fast and was finished in just eight months. On October 20 of the same year, when Ferruccio Lamborghini invited the press to the launch of the first Lamborghini car, the 350 GTV prototype, the completed main structure of the factory was already visible in the photograph’s background.

Right from the start, Lamborghini focused on the use of technologically advanced machinery, combining the artisan skills of the workers with the most advanced technology available – a value that remains at the heart of the company’s industrial vision today. In 1966, the two assembly lines, one dedicated to engines and mechanical components and the other focused on car assembly, were already supported by ancillary machinery.

Beyond that, the Lamborghini Miura debuted that year. Inspired by the beautiful names of the world of bullfighting, it initiated the brand’s naming tradition. With its central engine and fascinating body designed by Marcello Gandini and Nuccio Bertone, the Miura redefined the concept of sports cars in 1966 and earned the title “supercar” from a journalist.

On October 18, 1968, Lamborghini announced the imminent completion of three new industrial buildings that would strengthen the production facilities and create a modern, well-equipped test department. The photograph accompanying this press release is now iconic, as it shows – in addition to the department under construction – the successor model of the 400 GT and two Miura.

Production went from 67 Lamborghinis produced in 1965 to 425 in 1971, later falling to 55 in 1979 due to the economic crisis of the 1970s. The 1980s marked a resumption of production, reaching 470 cars produced in 1987 along with 300 marine engines.

Together with the Miura, the Countach represents the backbone of the Lamborghini tradition. Once again, Marcello Gandini and Nuccio Bertone created a unique, innovative design whose impact can be felt even today. Manufactured from 1974 to 1978 and crowned by a 25-year anniversary edition as well as the Countach LPI 800-4 presented in 2021, its legacy endures to this day.

In 1983, Lamborghini launched the development and use of carbon fiber for the first time. The new department could be set up thanks to know-how from Seattle, developed on the carbon-fiber and Kevlar components of the Boeing 767. The first carbon-fiber chassis prototype of the Countach Evoluzione was then created. It was the first use of composite materials by Lamborghini and an absolute first for a project of this type for a road car.

In 1990, destined to become the worthy heir of the renowned Miura and Countach, production of the Diablo started. This new supercar was wide, low, and futuristic. Just like its predecessors, it soon became a favorite among car enthusiasts around the world. In the following years, Lamborghini introduced several variations of the Diablo concept, all heavily contributing to the company’s legacy.

After joining the Audi Group in 1998, Lamborghini experienced rapid growth in development, production, and its workforce. In 2001, the headquarters underwent significant renovations, including a new office building, an expanded research and development area, a two-story museum, and upgrades to the assembly lines and employee dining facility. Completed in August 2001, the project totaled 155 million euros.

The first car developed under Audi’s aegis was the Murciélago in 2001. The legendary V12 supercar embodied the pinnacle of Italian automotive design and engineering. Renowned for its performance and design, it remains a symbol of the great development of Automobili Lamborghini.

On October 25, 2002, the opening of the Lamborghini Centro Stile was announced. The center was to open within a designated area of a new building, housing customer service, the center dedicated to classic Lamborghini cars, and the marine engine sector.

The company was again undergoing rapid growth, producing 1,305 cars with 624 employees. In 2006, with an impressive +30.4% growth compared with the previous year, 2,087 cars were produced.

In 2011, the Aventador was launched, equipped with a carbon-fiber monocoque design and manufactured entirely in Sant’Agata Bolognese. For the car’s body, made of 100% carbon fiber, Lamborghini decided on complete in-house production and launched the “CFK” – Lamborghini Carbon Production, further establishing Lamborghini’s leadership in the super sports car sector for the production and development of composite materials, which continues today.

Lamborghini Park opened that year as well, advancing two sustainability initiatives: biomonitoring with bees and an experimental study on CO2 capture and biodiversity in the Oak Forest. These projects are conducted with the Municipality of Sant’Agata Bolognese and the Universities of Bologna, Bolzano, and Munich.

Subsequently, Automobili Lamborghini introduced the Huracán to its lineup, an immensely coveted model that led to many different derivatives, as there was the Coupe, the Spyder, the RWD, the AVIO, the RWD Spyder, the Performante, the Performante Spyder, the EVO, the EVO RWD, the EVO RWD Spyder as well as the EVO Spyder, STO, Tecnica and Sterrato, delivered from 2014 to 2025.

In 2018, Lamborghini unveiled its groundbreaking third model, the Urus Super SUV. Production commenced in newly constructed facilities in Sant’Agata Bolognese, which included a dedicated Urus assembly line and an advanced finishing department for all Lamborghini models. The renovation also contained a LEED Platinum-certified office building, the highest energy and environmental certification in building design. Furthermore, it included a specialized test track with 13 SUV-specific surfaces, a new logistics warehouse, an expanded trigeneration power plant, and the “Energy Hub” for centralized energy management. Lamborghini launched the innovative “Manifattura Lamborghini” production model, blending artisanal craftsmanship with advanced, sustainable technologies.

In 2023, with the release of the HPEV Revuelto, a unique and innovative car that combines a new 12-cylinder engine with hybrid technology, the company started its journey towards a fully hybrid lineup in alignment with the “Direzione Cor Tauri” strategy. This was completed in 2024 when the Plug-In Hybrid Super SUV Urus SE and HPEV Temerario were added to the portfolio.

Presented in April 2024, the Urus SE is the world’s first Plug-In Hybrid Super SUV. It was unveiled featuring a new design, optimized aerodynamics, and unprecedented on-board technology. Thanks to its “two hearts,” thermal and electric, the torque and power values are the highest ever (800 CV), giving the SE a unique place in its category and achieving an 80% reduction in emissions.

Presenting itself as the new benchmark in the super sports car segment, the Temerario combines an entirely new twin-turbo V8 engine with three electric motors, providing a total power output of 920 CV. The twin-turbo V8 was designed and developed from scratch in Sant’Agata Bolognese and is the first and only production super sports car engine able to reach 10,000 rpm.