Profile of Audi in China

Back to overviewThe Chinese market has particular strategic importance for Audi. That’s why Audi cooperates with two partners to produce locally in addition to developing market-specific technologies and managing sales of its vehicles directly in the market. AUDI AG is represented in the world's largest single market by the subsidiary Audi China in Beijing, the joint venture FAW-Volkswagen with headquarters in Changchun, and since 2021, SAIC Volkswagen in Shanghai. As a result of the two-partner strategy implemented in 2021, Audi possesses its largest model portfolio in China to date. Furthermore, Audi has successfully launched the new EV brand “AUDI” in 2024 to reach new tech-savvy target groups.

AUDI will unveil the first production model at the Shanghai Auto Show in April 2025. Production is set to start and deliveries to commence only a few months later. With the Audi FAW NEV Company, Audi is laying more important groundwork for expansion of the local electric portfolio. Production of all-electric Audi models based on the PPE platform at a new plant in Changchun commenced in late 2024.

Audi in the Chinese market

The history of Audi in China goes back a long way: the company has had a presence there for more than 35 years. In 1988, it began its cooperation with the Chinese automaker First Automotive Works (FAW). As such, Audi was the first foreign premium manufacturer in the market and also the first to adapt its product portfolio to the specific needs of Chinese customers, for example by offering Audi models with extended wheelbases.

AUDI AG is represented in Beijing by its 100%-owned subsidiary, Audi China. More than 700 employees at Audi China coordinate the cooperation between AUDI AG and its partners, the joint venture FAW-Volkswagen with head office in Changchun and – since 2021 – SAIC Volkswagen in Anting (Shanghai). With its two partners, Audi manufactures vehicles at a total of seven locations: Changchun, Foshan, Tianjin, Qingdao, Anting (Shanghai), and Ningbo. Furthermore, Audi launched the new EV brand “AUDI” in late 2024 to reach new tech-savvy target groups.

One of the main focuses of Audi China is on the intensification of local research and development activities in order to offer market-specific technologies and products for the Chinese market. Audi China R&D develops models, products, and technologies that are specifically adapted to local customer requirements. Audi places particular emphasis on developing electronics, advanced driver assistance systems, market-specific connectivity features, and extended smart-cockpit features, i.e., intelligent operating and comfort functionalities. To integrate technologies and services from the digital Chinese ecosystem into its vehicles, Audi also enters joint ventures with Chinese tech corporations.

In 2024, Audi delivered more than 649,000 cars to our customers in China.

Audi production locations

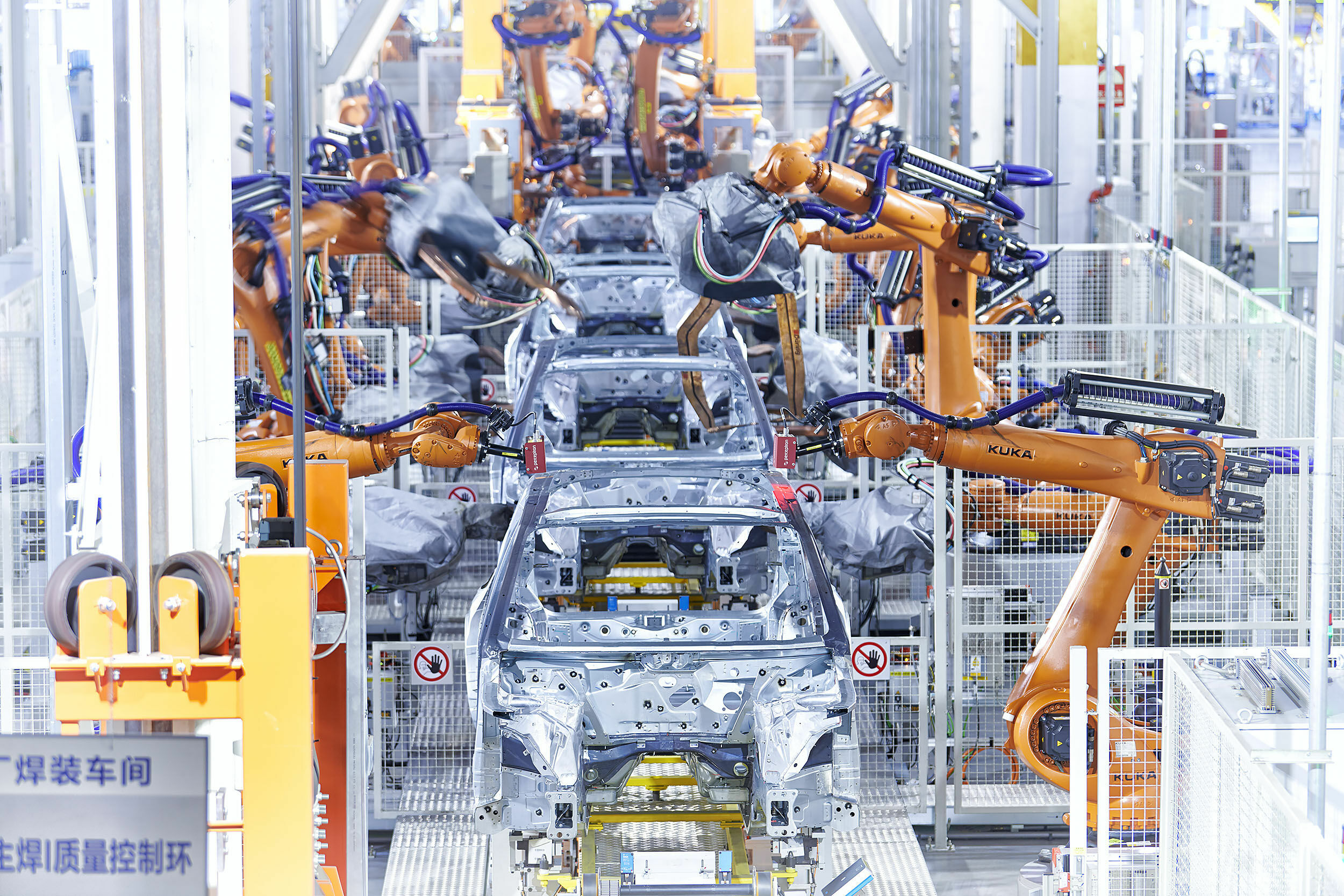

As the first premium manufacturer in the market, Audi was quick to embrace local production of market-specific models and brought innovative automotive and manufacturing technologies to China.

Audi models are currently being manufactured at a total of seven production sites belonging to the two partners, FAW and SAIC: Changchun, Foshan, Tianjin, Qingdao, Anting (Shanghai), and Ningbo – with a current production capacity of over 600,000 vehicles. With the establishment of Audi FAW NEV Company in Changchun as a new production site for all-electric models, Audi has expanded its capacities by more than 150,000 additional cars.

Automobile production in the joint venture with FAW-Volkswagen in Changchun in northeastern China encompasses the four principal areas of car manufacturing: pressing, body construction, paintwork, and assembly.

Following the establishment of the Audi FAW NEV Company Ltd., a state-of-the-art manufacturing facility was constructed in Changchun for all-electric Audi models. With series production beginning in late 2024, Audi is producing the two models Q6L e-tron and Q6L Sportback e-tron at the new site, followed by the Audi A6L e-tron later. The long-wheelbase versions are oriented towards the needs of Chinese customers. The plantwas built on around 150 hectares and, as the newest production facility within the Audi production network, it is setting new standards in terms of digitalization, efficiency, and sustainability. A central IT system that also includes the neighboring supplier park helps in efficiently controlling and monitoring all production steps. The cross-site environmental program “Mission:Zero” sets the parameters for sustainability, ensuring vehicle production is net carbon neutral. With an annual capacity of more than 150,000 vehicles, the new location makes a key contribution to the further electrification of the Audi product portfolio in China. The Audi FAW NEV Company is the first cooperation company with a majority Audi holding in China.

Finished at the end of 2013, the FAW-Volkswagen plant in the southern Chinese city of Foshan manufactures the Audi Q2 L based on the MQB platform and since 2019 the electric Audi Q2 L e-tron. In addition, the Audi Q4 e-tron is produced in Foshan.

Meanwhile, the Audi Q3 and the Audi Q3 Sportback are manufactured at a plant in Tianjin in northern China, which opened in 2018.

At Tianjin, the Audi transmission plant has also been manufacturing 7-gear S tronic transmissions at Volkswagen Automatic Transmission (Tianjin) Corporation Ltd. (VWATJ) for the locally produced Audi A4 L, Audi A6 L, and Audi Q5 L models since 2016.

Qingdao is the youngest location in the production network of FAW-Volkswagen. Opened in 2018, the plant is situated in Jimo, around 60 kilometers from Qingdao. In addition to automobile production with the Audi A3 Sportback and the Audi A3 L Sedan, the plant also possesses manufacturing facilities for high-voltage batteries.

Alongside cars from other Group brands, Chinese partner SAIC manufactures Audi models at two of its plants in Anting (Shanghai). The plant where the Audi A7 L is manufactured covers a total of 448,900 square meters (536,900 sq yd). The manufacturing facility for electric vehicles in Anting has been making an all-electric Audi model exclusively for China in the form of the Audi Q5 e-tron. On a total area of 406,000 square meters (485,600 sq yd), the electric vehicle plant includes production areas such as a press shop, body construction, a paint shop, a final assembly line, and a battery assembly facility.

SAIC manufactures the Audi Q6 Roadjet in Ningbo. The Ningbo plant is located in a developing area along Hangzhou Bay. It has a press shop, body construction, paint shop, and assembly hall, as well as a technology center, training center, and energy center.

Electrification in China

In 2022, Audi expanded its portfolio of battery electric vehicles (BEVs) by including the Audi Q4 e-tron. Together with its partner SAIC, Audi is offering the Q5 e-tron as a market-exclusive model. As the next step in its electrification strategy, the Audi FAW NEV Company in Changchun started production of all-electric medium- and top-range models based on the Premium Platform Electric (PPE). The first market-specific models from the Audi A6 e-tron and Audi Q6 e-tron model families will enter the Chinese market in 2025. In addition, Audi has launched the new EV brand “AUDI” to reach new tech-savvy target groups.

To promote the rapid development of a nationwide charging infrastructure, Audi is relying in part on brand-exclusive quick-charging stations, the Audi Charging Stations. In this way, Audi is building a nationwide high-power charging (HPC) network with a top charging power of up to 360 kilowatts at a maximum voltage of 1,000 volts. By the end of 2024, the Audi-branded charging network had already deployed 600 fast chargers in over 30 cities across the country, with charging services accessible via its premium digital ecosystem via the Audi MMI and Audi App.

Partnerships in sales, marketing, service

The global concept Audi Progressive Retail, embodied by a completely new, inviting, and progressive showroom architecture, interactive digital elements, and employees to spark enthusiasm for new technologies, will be gradually localized and rolled out in China and be tailored to Chinese customer demands in digitalization, electrification, and personalization.

With the foundation of the FAW Audi Sales Company, Audi has been consolidating its sales activities in China in Hangzhou in the southeast of the country since the end of 2022. This makes Hangzhou, a dynamic and innovative metropolis with a population of ten million, another attractive Audi location in China. To provide a holistic customer journey in China, the company has also continuously upgraded their offline touchpoints and expanded its innovative sales setup to deliver a progressive retail experience.

By the end of 2024, FAW Audi upgraded over 550 4S dealerships with the latest brand design language.

Meanwhile, SAIC Audi also diversified its network, establishing the "SAIC Audi Customer Center" to provide users with comprehensive brand and product experiences. Currently, SAIC Audi operates nearly 190 points of sale covering over 100 prioritized premium automotive cities.

In addition to models that Audi produces locally, 30 more models are available in China as imports.

Research and development

Since 2013, Audi has relied on its own local development team in China, which develops market-specific models and technologies.

Audi is continuously intensifying its development activities in China with a clear product and technology roadmap. At the end of 2022, the Audi China development team moved into a new development center in Beijing, the Audi China Building. Located in the Chinese capital’s northern Central Business District, the 6,000-square-meter building houses a design studio, an electronics development laboratory, and predevelopment workshops, among other things. In the development of future technologies, Audi China R&D is investing systematically in the following areas: smart cockpits, local adaptation, and market-specific contents of new electronics architectures, China-specific driver assistance systems and automated driving systems, customized connectivity offerings, and local homologation. In addition, Audi uses synergies within the VW Group in China and works with the corporation-wide Hub CARIAD software hub.

In the areas of connectivity and infotainment in particular, Audi is expanding its cooperation with local tech companies and start-ups. To this end, Audi China R&D is collaborating with leading Chinese tech companies.

To promote the rapid development of a nationwide charging infrastructure, Audi is relying in part on brand-exclusive quick-charging stations, the Audi Charging Stations. In this way, Audi is building a nationwide high-power charging (HPC) network with a top charging power of up to 360 kW and a maximum voltage of 1,000 V. Audi has continued to expand its premium charging network in China, which has grown considerably in 2023 to deliver fast, convenient, and worry-free charging. By the end of 2023, the Audi-branded charging network already has 600 fast charging pillars deployed in over 30 cities across the country, with charging services accessible via its premium digital ecosystem involving the Audi MMI and Audi App. For maximum convenience, the charging stations feature Plug and Charge, which starts charging automatically with no need for an app or map verification.

Partnerships in sales, marketing, service

The global concept Audi Progressive Retail, embodied by a completely new, inviting, and progressive showroom architecture, interactive digital elements, and employees to spark enthusiasm for new technologies, will be gradually localized and rolled out in China and be tailored to Chinese customer demands in digitalization, electrification, and personalization.

With the foundation of the FAW Audi Sales Company, Audi has been consolidating its sales activities in China in Hangzhou in the southeast of the country since the end of 2022. This makes Hangzhou, a dynamic and innovative metropolis with a population of ten million, another attractive Audi location in China. To provide a holistic customer journey in China, the four Rings have also continuously upgraded their offline touchpoints and expanded their innovative sales setup to deliver a progressive retail experience.

By the end of 2023, FAW Audi has upgraded over 540 4S dealerships in the latest brand design language and opened eight city showrooms.

Meanwhile, SAIC Audi also diversified its network format, establishing the "SAIC Audi Customer Center" to provide users with comprehensive brand and product experiences. Currently, SAIC Audi operates nearly 160 points of sale covering over 80 prioritized premium automotive cities. SAIC Audi's customer journey is flanked by innovative retail formats.

On January 1, 2022, SAIC Audi opened the House of Progress (HoP) in Shanghai, the largest store of its kind in the world: The new flagship store offers a fascinating brand experience on an area of 2,400 square meters. The concept consists of an extraordinary mixture, characterized by art and high-tech. In addition to the experiential character, the House of Progress is also intended to stand for efficient customer service and symbolically demonstrate the quality and customer proximity of SAIC Audi in all phases of the customer life cycle.

In addition to models that Audi produces locally, 30 other models are available in China as imports.

Research and development

Since 2013, Audi has relied on its own local development team in China, which develops market-specific models and technologies.

Audi is continuously intensifying its development activities in China with a clear product and technology roadmap. At the end of 2022, the Audi China development team moved into a new development center in Beijing, the Audi China Building. Located in the Chinese capital’s northern Central Business District, the 6,000-square-meter building houses a design studio, an electronics development laboratory, and predevelopment workshops, among other things. In the development of future technologies, Audi China R&D is investing systematically in the following areas: smart cockpits, local adaptation, and market-specific contents of new electronics architectures, China-specific driver assistance systems and automated driving systems, customized connectivity offerings, and local homologation. In addition, Audi uses synergies within the VW Group in China and works with the corporation-wide Hub CARIAD software hub.

In the areas of connectivity and infotainment in particular, Audi is expanding its cooperation with local tech companies and start-ups. To this end, Audi China R&D is collaborating with leading Chinese tech companies, such as Tencent for integration of WeChat into Audi models. The Android-based open service platform seamlessly integrates apps and WeChat mini-programs into the MMI and allows third-party providers to develop customized WeChat mini-programs for the Audi MMI.

Audi production in Changchun

FAW-Volkswagen Automotive Company Ltd.

Founded: 1988

Plant manager: Gao Qizheng, Juergen Russer

Models: Audi A4 L, Audi A6 L, Audi Q5 L, Audi Q5 L Sportback, Audi e-tron

Production (2023): 472,435 vehicles

Audi production in Foshan

FAW-Volkswagen Automotive Company Ltd.

Founded: 2013

Plant manager: Wang Wei, Stefan Depka

Models: Audi Q2 L, Audi Q2 L e-tron, Audi Q4 e-tron

Production (2023): 40,624 vehicles

Audi production in Tianjin

FAW-Volkswagen Automotive Company Ltd.

Founded: 2018

Plant manager: Dr. André Richter

Models: Audi Q3, Audi Q3 Sportback

Production (2023): 63,713 vehicles

Audi production in Qingdao

Location: FAW-Volkswagen Automotive Company Ltd.

Founded: 2018

Plant manager: Liu Dong, Bruno Torres

Models: Audi A3 Sportback, Audi A3 L Sedan

Production (2023): 63,897 vehicles

Audi production in Anting (Shanghai)

SAIC Volkswagen Automotive Company Ltd.

Founded: 2021 (start of production of Audi A7L: September 2021)

Plant manager: Cheng Liang (Anting plant), Xu Zhiqin, Oliver Wollinsky (MEB plant)

Models: Audi A7 L, Audi Q5 e-tron

Production (2023): 19,281 (Anting plant), 5,506 (MEB plant) vehicles

Audi production in Ningbo

SAIC Volkswagen Automotive Company Ltd.

Since: 2022

Plant manager: Chen Jianfeng, Frank Schemmel

Models: Audi Q6 Roadjet

Production (2023): 5,151 vehicles

Audi electric vehicles production in Changchun

Audi FAW NEV Company Ltd.

Founded: 2021; construction started in 2022

Plant manager: Helmut Stettner

Models: all-electric Audi models starting from Audi A6 e-tron and

Audi Q6 e-tron series

Planned annual production capacity: more than 150.000 vehicles