Search

All search results for "power electronics"

(601)

MHEV plus: the next generation of hybridization at Audi

MHEV plus: the next generation of hybridization at Audi

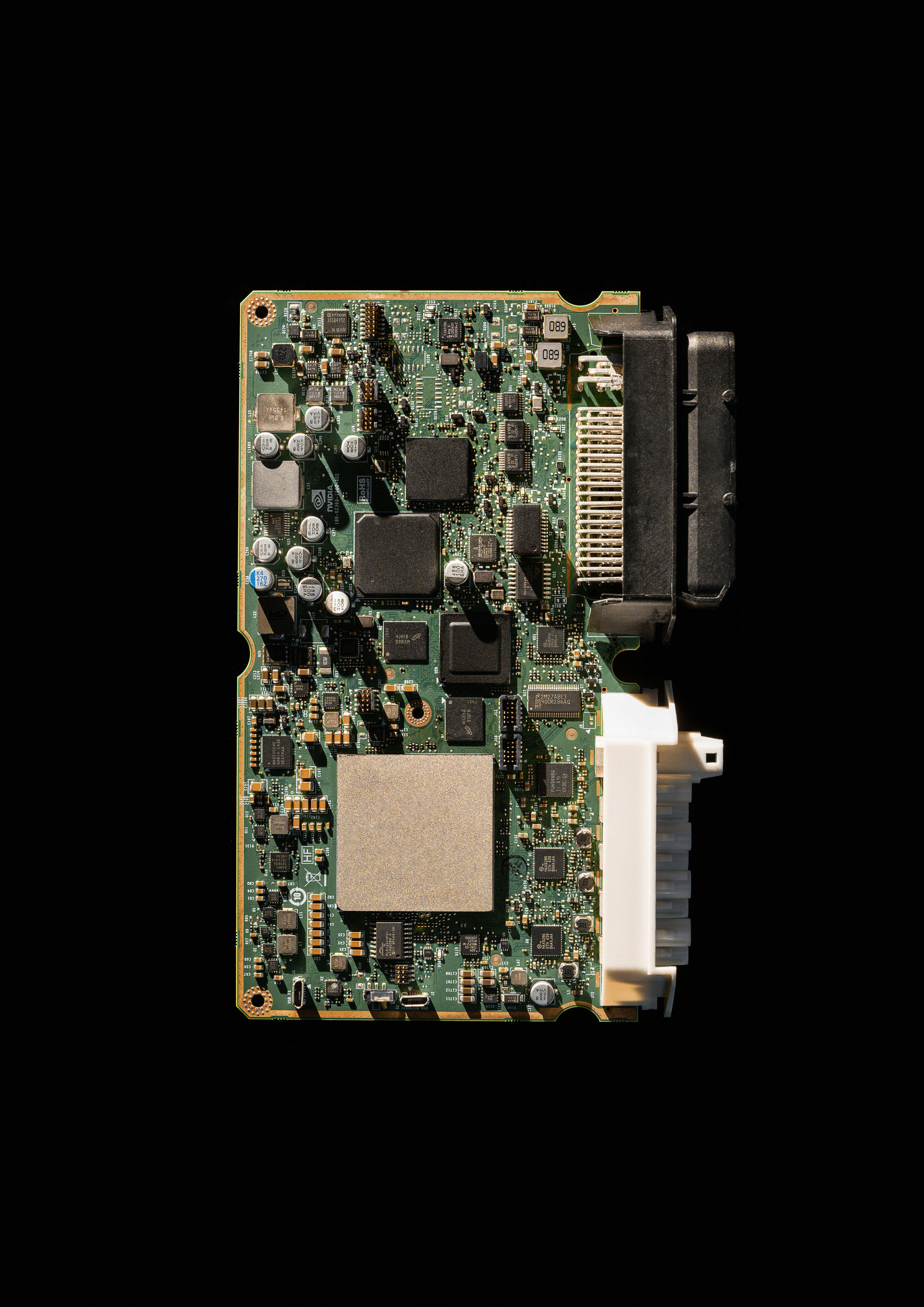

The PTG, which can be fully coupled or decoupled, features integrated power electronics and an electric motor that enables partially electric driving. This reduces consumption and makes for an even smoother driving experience.

“With the new MHEV plus technology, we are driving forward electrification in our new combustion-engine vehicles based on the Premium Platform Combustion that is tailored to the needs of our customers,” says Geoffrey Bouquot, Member of the Board of Management for Technical Development at AUDI AG. “This will strengthen our product portfolio of all-electric models, plug-in hybrids, and vehicles with efficient combustion engines.” MHEV plus offers attractive functions such as partially electric driving, electric boosting, and a significant increase in efficiency and comfort. The mild hybrid system in the new Audi A5 and Q5 consists of three main components: the compactly designed new powertrain generator (PTG) with integrated power electronics and a permanently excited synchronous motor (PSM), a 48-volt battery, and the belt alternator starter (BAS). The components of the 48-volt system are liquid-cooled to achieve optimum operating conditions. The architecture of the MHEV plus system can be integrated into various models with front and quattro drivetrains based on the Premium Platform Combustion (PPC). Situation-specific liquid cooling of the power electronics and the electric motor enables the components to be operated in optimum operating conditions in order to meet power and torque demands in all operating states. The new MHEV plus technology enables purely electric operating states and can also support the combustion engine. The system thereby increases performance and agility while also reducing fuel consumption and CO2 emissions.

New Audi A5 e-hybrids combine dynamics, efficiency, and long electric range

New Audi A5 e-hybrids combine dynamics, efficiency, and long electric range

Audi offers both the Avant and Sedan as e-hybrid quattro in two power levels with up to 270 kilowatts of total output Increased efficiency and power availability due to HV battery with more capacity, higher energy density, and smart recuperation strategy Intelligent hybrid management ensures optimum operating strategy and an electric range of up to 110 kilometers (68 mi)

Built on the Premium Platform Combustion (PPC), the new Audi A5 is welcoming additional members to its family. Alongside the pure combustion engine models, Audi is now offering two plug-in hybrid electric vehicle (PHEV) models in two power levels for the A5 series for the first time. Customers will benefit from greater comfort and technical innovations for their daily mobility. The new generation of HV batteries boasts around 45 percent higher capacity. The increased regenerative braking performance contributes to an electric range of up to 110 kilometers.

With the new A5 family, Audi has embarked on the next chapter in its successful history of mid-size cars with a more striking design language, state-of-the-art combustion engine technology, and a new operating concept. The new plug-in hybrid models for the A5 series offer customers even more flexibility and efficiency. To make the new PHEVs even more recognizable, Audi is introducing the technology designation “e-hybrid” with immediate effect. “As part of our model initiative, we are significantly expanding our range of plug-in hybrids in 2025,” says Audi CEO Gernot Döllner. “Outputting up to 270 kilowatts, our new generation of plug-in hybrid models offers a sporty and comfortable driving experience as well as a harmonious balance between performance and efficiency.” Geoffrey Bouquot, Member of the Board of Management for Technical Development at AUDI AG, adds: “The increased electric range of our new plug-in hybrids enables our customers to cover the majority of their daily journeys using only electric power.

A class act: the new Audi A6 Avant

A class act: the new Audi A6 Avant

Economical and powerful: MHEV plus technology The MHEV plus mild hybrid technology drives play a key role in the outstanding driving experience. In addition to the 2.0 TDI four-cylinder with 150 kW (204 PS), the 3.0 TFSI six‑cylinder with 270 kW (367 PS) also features this type of partial electrification. The MHEV plus system supports the combustion engine, increases performance and driving comfort, and reduces carbon emissions. The system consists of three main components: a 48-volt battery, the belt alternator starter (BAS), and the powertrain generator (PTG) with integrated power electronics. The PTG enables fully electric parking and maneuvering. The A6 Avant also runs on electric power when driving slowly in the city, in slow-moving traffic, or outside city limits when coasting to the next village. Furthermore, the PTG produces additional torque up to 230 Newton meters and up to 18 kW (24 PS) of power when starting off or overtaking. When decelerating, the PTG can recover up to 25 kW of energy. A synthesis of sportiness and comfort: the chassis and steering The new A6 Avant perfects the synthesis of sportiness and comfort thanks in part to optional features such as all-wheel steering and adaptive air suspension, the latter of which regulates body height and shock absorption. Moreover, the quattro sport differential ensures even greater agility. The standard progressive steering of the new A6 Avant now responds even more directly. Compared to its predecessor, the entire path from the steering wheel to the wheels is designed to be stiffer. This includes the torsion bar, the rigidly bolted steering rack, and the stiffer control arm bushings. Camber on the front axle has also been slightly increased.

Back then, the twin-turbo V6 had a power output of 279 kW (380 PS). The new RS 4 Avantnow puts out 331 kW (450 PS), which equals an output of 155.5 PS per liter. This means that the RS 4 Avantonly needs between 3.9 and 4.1 seconds (depending on equipment) to go from zero to 100 km/h (62 mph). The TFSI engine weighs just 182 kg (401.2 lbs.), which is 31 kilograms (68.3 lbs.) less than the V8 engine in the 2012 predecessor model. This improves the gross weight and the axle load distribution—two prerequisites for impressive performance. The twin-turbo V6 applies an impressive 600 Nm of torque to the crankshaft in a broad engine speed range from 1,900 to 5,000 rpm. The RS dynamic package increases the electronically governed top speed from 250 to 280 km/h (155 to 174 mph), in conjunction with the optional competition packages to 290 km/h (180 mph). The two turbochargers of the 2.9 TFSI are each assigned to a cylinder bank and build up a boost pressure of up to 1.5 bar. Like with all V6 and V8 engines from Audi, the turbochargers are installed within the 90-degree interior “V” of the cylinder banks, and thus the exhaust side of the cylinder heads is on the inside, while the intake side is on the outside of the engine. This layout enables compact construction and short gas flow paths with minimal flow losses, allowing the 2.9 TFSI to respond especially quickly to movement of the accelerator pedal.

Progressive and efficient: quattro all-wheel drive

Progressive and efficient: quattro all-wheel drive

An electronically controlled multi-plate clutch distributes torque between the front and rear axles over a wide range, as required by the specific driving situation. For excellent fuel efficiency, the rear axle of the quattro ultra is automatically decoupled under partial load insofar as the driving situation allows. When taking corners dynamically, accelerating sharply, or when the friction coefficient of the road surface requires it, the quattro system’s electronically controlled multi-plate clutch connects the front and rear axles and distributes the tractive force flexibly to where it is needed. If you accelerate hard out of a corner, power is distributed more towards the rear. In this driving situation, the power distribution between the front and rear axles is around 30:70. Another component of the V6 TFSI powertrain is the optional quattro sport differential on the rear axle, which actively and completely variably distributes torque between the rear wheels. Unlike a conventional limited-slip differential, the sport differential can further accelerate the outer wheel when cornering dynamically, meaning it applies more torque to that wheel. This makes the A6 Avant able to turn more precisely into the curve. The sport differential counteracts the tendency to understeer early on and ensures enhanced agility. In the dynamic Audi drive select mode, the handling is more rear-biased. The equipment, data and prices specified in this document refer to the model range offered in Germany. Subject to change without notice; errors and omissions excepted.

The new Audi A6 Avant: Business class meets sports elite

The new Audi A6 Avant: Business class meets sports elite

The Audi A6 Avant models are based on the Premium Platform Combustion (PPC), powered by modern gasoline and diesel engines that are more efficient and dynamic thanks to the mild hybrid technology MHEV plus. Additional highlights include intuitive operating and infotainment concepts, new digital lighting technology, and intelligent driver assistance systems. Since 1977, the name Avant has stood for vehicles that combine sporty and elegant design, superior functionality, and outstanding driving dynamics. Forty-eight years after the debut of the Audi 100 Avant, the A6 Avant is ushering in a new era.

Audi CEO Gernot Döllner: “We are writing the next chapter in our Avant history: The new Audi A6 unites an elegant and dynamic design with exceptional aerodynamics. Efficient yet high performance drive systems and cutting-edge suspension technology combine sportiness with a high level of comfort, making traveling in the A6 a first-class experience.” With this model, the company is also continuing its major product initiative that began in 2024. The modernization and rejuvenation of the product portfolio is part of the Audi Agenda, with which Audi is positioning itself for the future in the face of intensified competition. “With the A6, we are now renewing an important model series,” said Döllner. Like the new Q5 and A5, the new A6 Avant is also based on the Premium Platform Combustion (PPC). The E³ 1.2 electronics architecture ensures modern connectivity, updates, and digitalization features in all new models.

With the standard RS sport suspension, theAudi RS 4 Avant is seven millimeters (0.3 in.) lower than the S4 base model with sport suspension. The RS sport suspension plus with Dynamic Ride Control (DRC) enables even more agile handling and is available upon request. This integrated roll and pitch stabilizer consists of a special damper system that counteracts the movements of the vehicle body with no delay without the use of electronics. When the car is turning into or traveling around a bend, the damper response is altered so that the vehicle’s movements are significantly reduced along the longitudinal axis (roll) and the transverse axis (pitch). The dampers are each connected diagonally to a central valve via two separate oil lines. The valves provide the necessary compensating volume via internal pistons with the gas-filled compartment behind them. When the vehicle is steering into and traveling around a bend, an oil flow is generated between the diagonally opposite dampers via the central valve, thus creating additional damping force. When one side is cushioned, the damping characteristics are altered such that roll and pitch movements are almost eliminated. As a result, this highly responsive damper system ensures that the RS models are particularly precise when negotiating bends. With the aid of Audi drive select, the driver can influence the damper response in three stages and thereby personalize the driving experience. The current generation of dampers with integrated switching valve is compact and lightweight.

Profile of Audi in China

Profile of Audi in China

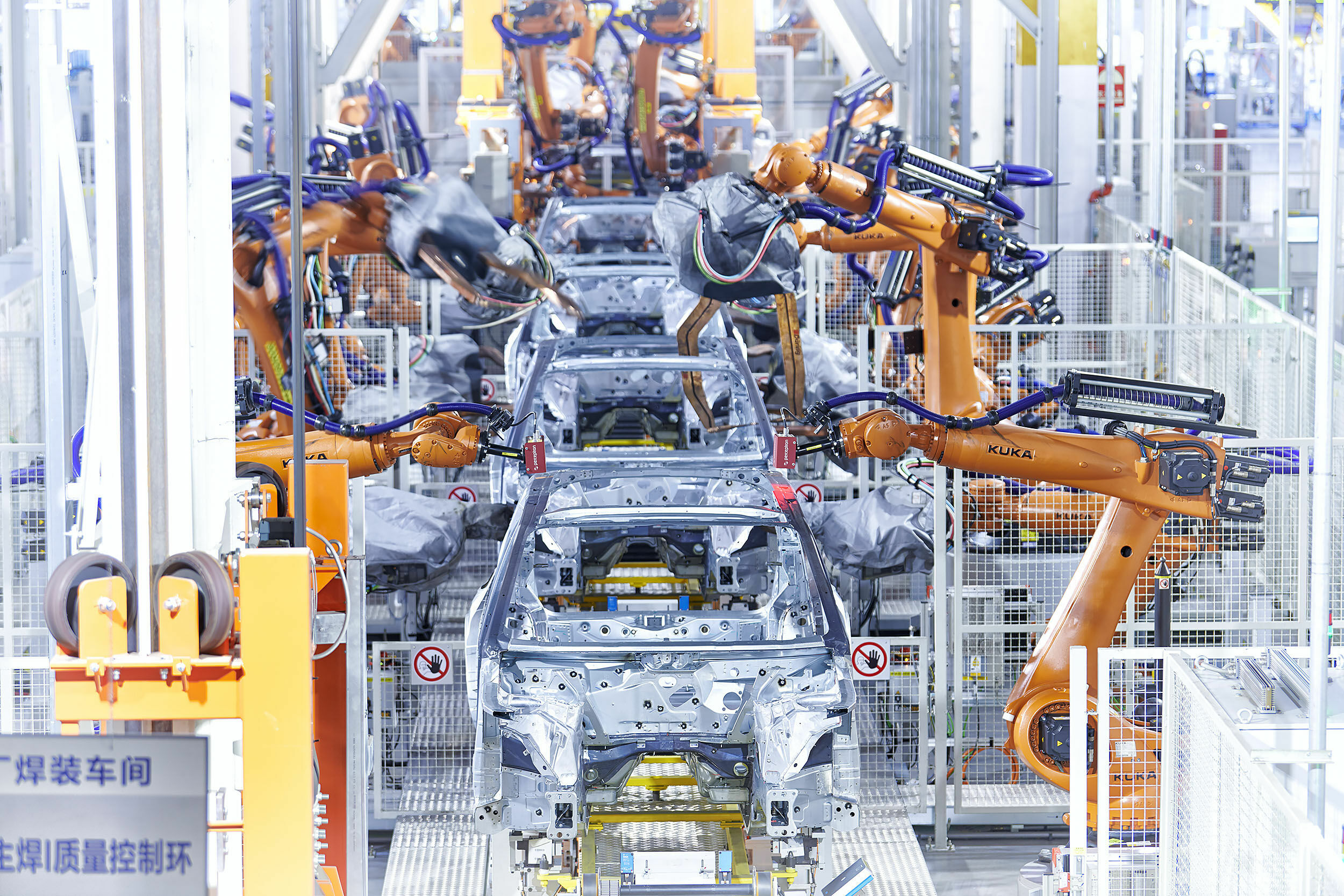

Audi places particular emphasis on developing electronics, advanced driver assistance systems, market-specific connectivity features, and extended smart-cockpit features, i.e., intelligent operating and comfort functionalities. To integrate technologies and services from the digital Chinese ecosystem into its vehicles, Audi also enters joint ventures with Chinese tech corporations. In 2024, Audi delivered more than 649,000 cars to our customers in China. Audi production locations As the first premium manufacturer in the market, Audi was quick to embrace local production of market-specific models and brought innovative automotive and manufacturing technologies to China. Audi models are currently being manufactured at a total of seven production sites belonging to the two partners, FAW and SAIC: Changchun, Foshan, Tianjin, Qingdao, Anting (Shanghai), and Ningbo – with a current production capacity of over 600,000 vehicles. With the establishment of Audi FAW NEV Company in Changchun as a new production site for all-electric models, Audi has expanded its capacities by more than 150,000 additional cars. Automobile production in the joint venture with FAW-Volkswagen in Changchun in northeastern China encompasses the four principal areas of car manufacturing: pressing, body construction, paintwork, and assembly. Following the establishment of the Audi FAW NEV Company Ltd., a state-of-the-art manufacturing facility was constructed in Changchun for all-electric Audi models. With series production beginning in late 2024, Audi is producing the two models Q6L e-tron and Q6L Sportback e-tron at the new site, followed by the Audi A6L e-tron later. The long-wheelbase versions are oriented towards the needs of Chinese customers. The plantwas built on around 150 hectares and, as the newest production facility within the Audi production network, it is setting new standards in terms of digitalization, efficiency, and sustainability.