Search

Water recycling at Audi Brussels: A milestone for sustainable water use

Water recycling at Audi Brussels: A milestone for sustainable water use

The company’s vision is to create a circular economy where resources such as plastics, water, and other raw materials are used in closed cycles. Pilot projects are intended to pave the way for a long-term circular system. 1Audi understands net-zero CO2 emissions to mean a situation in which, after other possible reduction measures have been exhausted, the company offsets the carbon emitted by Audi’s products or activities and/or the carbon emissions that currently cannot be avoided in the supply chain, manufacturing, and recycling of Audi vehicles through voluntary offsetting projects carried out worldwide. In this context, carbon emissions generated during a vehicle’s utilization stage, i.e. from the moment it is delivered to the customer, are not taken into account.

Audi Ingolstadt: net carbon neutral production since January 2024

Audi Ingolstadt: net carbon neutral production since January 2024

Audi’s vision is to create a circular economy where resources such as plastics, water, and other raw materials are used in closed cycles. In Ingolstadt, for example, the company has been operating a process water supply center with a membrane bioreactor since 2019 to use water more efficiently. This year, Audi became the first premium car manufacturer to join the Alliance for Water Stewardship (AWS). Audi plans to halve the ecologically weighted water consumption at its production sites worldwide by 2035. The plant in San José Chiapa, Mexico, which has been building cars without producing any wastewater since 2018, stands as a role model for the responsible use of water resources. Finally, as a member of the “Biodiversity in Good Company” initiative, the brand with the four rings is also committed to protecting biodiversity at all its sites. The open spaces at the external site in Münchsmünster, which are designed to remain close to their natural form, are among the company’s largest measures in this area. On some 17 hectares of the site, a habitat has been created for numerous animal and plant species. The 360factory and sustainable land use Audi is also focusing on sustainability in the further development of its sites: Audi Production is using the transition to e-mobility to comprehensively transform its global production network and has a clear vision for the production of the future with the 360factory. As part of this holistic, sustainable approach, Audi is modernizing, digitalizing, and transforming its existing plants for the future. With the 360factory, Audi can achieve even greater flexibility and efficiency in production without sealing additional areas for new buildings. When it comes to sustainable land use, Audi is going one step further by revitalizing a former industrial site. The incampus in the south of Ingolstadt is also integrated into the company’s sustainability activities as a branch of the main plant.

New panes from old ones: starting this fall, recycled glass will be standard in the Audi Q4 e-tron German Award for Sustainability Projects goes to “GlassLoop” Audi focuses on circular economy at sustainability conference

For the windshields in the Audi Q4 e-tron, the company with the four rings will use glass made of up to 30 percent recycled material from car windows damaged beyond repair in the future. In doing so, Audi will successfully shift the “GlassLoop” pilot project into standard production. Audi, in cooperation with its partner companies, is the first premium auto manufacturer to set up a glass cycle of this kind. Until now, car windows damaged beyond repair – mainly windshields and panoramic roofs – have been used for less demanding purposes, such as bottles or insulation, in what is known as downcycling. The pilot project was the first to demonstrate that glass could be reused at comparable quality. Audi will show just how that works from June 14 to 16 at the 2023 GREENTECH FESTIVAL in Berlin. The company has supported the sustainability conference as a founding partner since 2020.

Together with Reiling Glas Recycling, Saint-Gobain Glass, and Saint-Gobain Sekurit, Audi’s “GlassLoop” project is showing how material cycles can be put into serial production. The partner companies spent about a year jointly testing ways to make new windshields for the Audi Q4 e-tron out of defective car glass. Now the process is ready for standard production: first, the car windows are broken up into small pieces using an innovative recycling process. Then all non-glass elements, like glue residue, are eliminated. The partners melt down the glass granulate obtained in this way and feed it into the production process for automotive plate glass. The secondary content of the glass produced in this way is up to 30 percent.

CEO Markus Duesmann: “China is getting on the sustainability train, and our model initiative is the perfect response”

CEO Markus Duesmann: “China is getting on the sustainability train, and our model initiative is the perfect response”

On the circular economy… “The circular economy is a major lever because any material we recycle, we don’t have to regenerate. We have multiple projects underway to achieve this. With our “MaterialLoop” project, Audi is taking the next steps in being able to recycle more and more materials from end-of-life vehicles in automobile production over the next few years.” On the mobility transition in China, Europe and the U.S.... “China is getting on the sustainability train. In the premium segment, we expect more than half the vehicles sold there to be all-electric as early as 2026.” “We take our Chinese competitors very seriously. But we also have the perfect response with ten new all-electric Audi models to launch in the next two years.” “The U.S. is creating a big impact with the Inflation Reduction Act (IRA). I wish Europe would show the same clarity in industrial policy.” “I believe it’s not just important but right for Europe to set ambitious targets for e-mobility. Because these targets create the pressure to develop new technologies, and that’s where our skillset lies.” For more information on the Better Future Conference, please click here.

Along with the Q4 e-tron, the Sustainability Table provides information about the circular economy and sustainable collaboration. The heart of the pavilion is the “Blog of Progress” in the open rotunda, which spatially links both of the upper exhibition levels with the entrance level. The blog’s real-time content is generated from the Audi brand’s daily updated highlight subjects and brand focal points. Thanks to a social media installation, anyone who is interested can sit in the back seat of a concept car from the sphere family at the end of the tour.

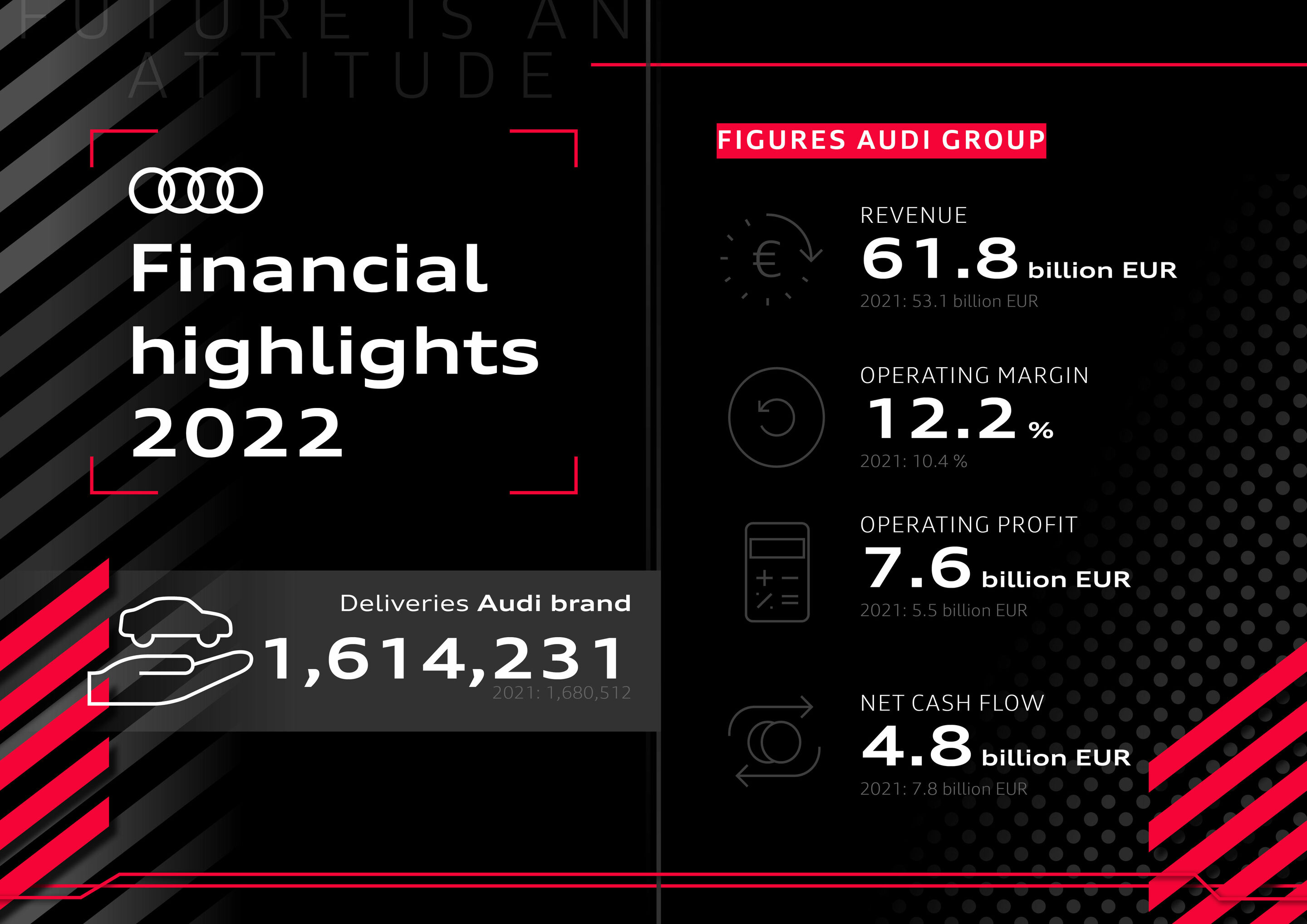

2022 fiscal year: Record operating profit for Audi

2022 fiscal year: Record operating profit for Audi

In positioning itself for a sustainable future, AUDI AG is also building its automotive value chain on the basis of the circular economy. Audi aims to steadily increase the share of recycled materials in the Audi fleet over the next few years. In turn, this will enable the company to reduce its models’ environmental footprint. Direct access to secondary materials is also likely to help improve long-term supply security. Together with 15 partners from the research, recycling, and supplier sectors, the brand with the four rings launched the MaterialLoop pilot project in October 2022. The company and the project partners are investigating reusing materials from cars that have reached the end of their life cycle for the production of new vehicles; around 100 end-of-life vehicles have already been dismantled. This is just one of many circular economy projects at Audi. The Audi plants in Neckarsulm, Ingolstadt, and Győr in Hungary, as well as the Volkswagen plant in Bratislava, are already implementing the Aluminum Closed Loop. The Audi Group is continuing to accelerate its transformation into a provider of sustainable, connected premium mobility: From 2023 to 2027, the Company will invest two-thirds of its outlays, or around €28 billion, in the future fields of electrification and digitalization. Audi CEO Duesmann: “Our focus on sustainable goals will shape our actions in the short, medium, and long term. The future investments from the current planning round confirm this clear path.” Group operating profit at record level Audi Group’s operating profit reached €7,550 (2021: 5,498) million, an increase of 37.3 percent. The operating margin also increased significantly to 12.2 (2021: 10.4) percent. In addition to strong market performance, the positive effects of securing raw materials contributed significantly to these record results.

CEO Markus Duesmann: “We are on the verge of the biggest product initiative in our history”

CEO Markus Duesmann: “We are on the verge of the biggest product initiative in our history”

That’s why the circular economy plays such an important role for us. In the future, we will recycle secondary materials from end-of-life vehicles back into the production of our cars. As part of our MaterialLoop pilot project, we are working with suppliers, recycling companies and academic partners to upskill in this area.” Jürgen Rittersberger: “At Audi, ESG goes beyond the product. We are convinced that a sustainable business model includes not only environmental considerations but also social responsibility. We have our performance measured by an independent rating agency based on strict criteria.” On the outlook for 2023 … Jürgen Rittersberger: “We have again set ambitious annual goals for 2023, even as general conditions will remain challenging.” Markus Duesmann: “Demand for e-mobility remains high. In January and February 2023, our sales of all-electric vehicles worldwide were up almost 40% compared to the same months last year. February also marked the launch of the Q8 e-tron in most European countries. We have some 20,000 pre-orders on the books, confirming that demand for sustainable electric mobility is booming.” A lot of additional information concerning the Audi Annual Media Conference is available at the Audi MediaCenter.

Live stream of Audi’s 2023 Annual Media Conference: Business figures and the balance sheet at a glance

Live stream of Audi’s 2023 Annual Media Conference: Business figures and the balance sheet at a glance

Annual Media Conference Thursday, March 16, 2023 Starting at 11:00 AM (CET) > Up 44 percent year-over-year: Audi delivers over 100.000 electric vehicles in 2022 > MaterialLoop pilot project: Audi tests the circular economy potential of end-of-life vehicles