Digital planning of production halls

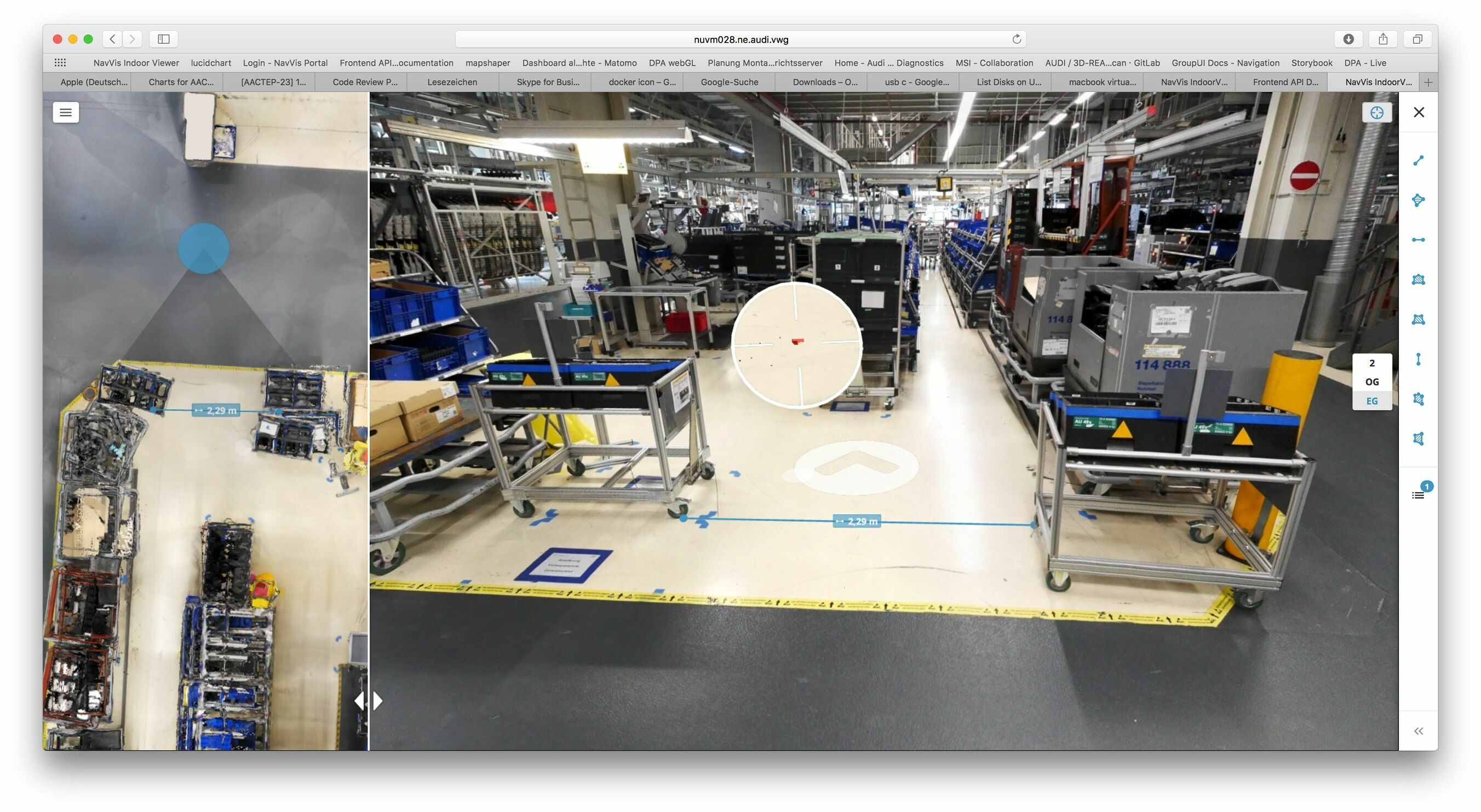

Planning production halls from home? Sounds impossible – but it is already a reality at the Audi Neckarsulm site – more specifically: a digital reality. Using special software and hardware, production halls and entire buildings have been scanned in 3D. The three-person Audi team led by project manager Andre Bongartz has been working together with the Munich-based start-up NavVis for a year. The scan results in a virtual model of the production site. This can be used as a basis for planning production without being on location. At the same time, the 3D scan generates a point cloud that records every machine and system. With the aid of machine learning, the virtual model of the hall is then linked with the point cloud so that the entire hall, including all machines, systems, and shelves, can be accessed virtually. This not only saves Audi employees a great deal of time and costs but also enables site-independent planning. “Especially now, during the coronavirus pandemic, our digital planning system provides enormous advantages: Planers can measure the production halls from home and thus plan systems precisely without even having a pocket rule in their hands,” according to Bongartz.

In the future, all production halls at the Neckarsulm site will be scanned digitally. Apart from that, other use cases, such as indoor navigation and an augmented reality (AR) planning application will be implemented as part of the 3D scan.