Audi to become first car manufacturer to launch second-generation prelube oils

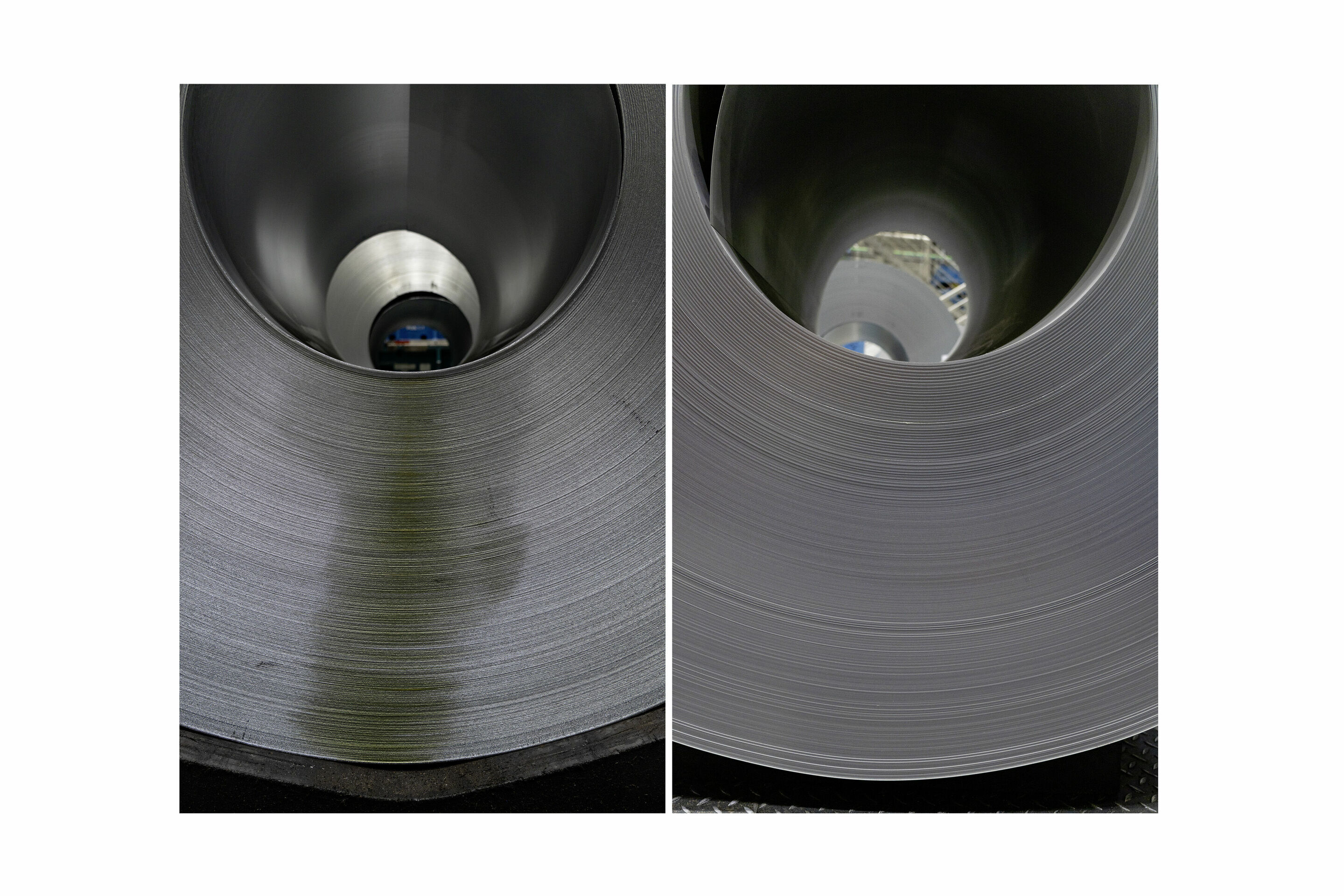

The Prelube protective film applied by the steel producers prevents corrosion and ensures that the process of forming the flat sheets into individual pieces in the Audi press shop quite literally runs like a well-oiled machine. The all-new basic lubrication “Prelube II” for steel coils in the press shop saves 40 metric tonnes of oil every year. With the conventional lubrication Prelube I (left), one gram of oil is applied over every square meter of sheet steel. With the new lubrication class Prelube II (right), however, just 0.7 grams of oil are required for every square meter – and with almost identical processing parameters. The new oil class creates a protective film on the surface of a metal sheet that is thicker and does not run off.

Image No:

A212793

Copyright: AUDI AG

Rights: Use for editorial purposes free of charge

Copyright: AUDI AG

Rights: Use for editorial purposes free of charge