Circular economy

Circular economy: keeping materials in the cycle with no loss of quality

The circular economy is an alternative to linear economies, which primary rely on easily accessible primary raw materials and low-cost energy. In simple terms, the two concepts differ in their use of resources. In a linear economy, raw materials are processed once and disposed of after use. In contrast, a circular economy works by reprocessing raw materials multiple times in their original quality and reusing them again and again for the production of goods and commodities. Key steps in this approach include the maintenance, repair, refurbishment, and finally, recycling of parts and components. The circular economy is based on the idea that all parts can be used sustainably, especially if they are in operation for as long as possible and if they are used for their initial manufactured purpose without being downcycled. Among other benefits, the reuse of valuable resources can help reduce our dependency on critical primary raw materials. It can also reduce the carbon footprint when the processing of used materials results in lower emissions than the production of new primary materials.

For all these reasons, Audi views the responsible use of raw materials as a central aspect of future-oriented automobile production. The aim is to develop and produce vehicles in a more resource-efficient and recycling-friendly manner, to keep them in use for as long as possible, and to recycle them to the best possible extent at the end of life. After a vehicle’s utilization phase, its materials are returned to the value chain, capturing more key resources in ‘closed cycles’ where they remain in use and decrease the need for new materials. In this endeavor, Audi follows a holistic concept based on the principles of reduce, reuse, and recycle.

Reduce: fewer primary materials, longer utilization phase

The reduce principle encompasses measures during the production process and the downstream utilization phase. Two basic aspects are at play here: firstly, the efficient use of materials, and secondly, extending the product life cycle, for example by repairing and reconditioning vehicles. In the earliest stages of development, a great deal of influence can be exerted through the choice of materials. When vehicles are designed ‘from the ground up’ with the recyclability of primary materials in mind, it becomes easier to facilitate the recycling of parts later on. This can include the use of so-called mono-materials, which do not consist of different materials that would need to be separated out to make recycling possible.

The reduce principle is also applied in production and is part of Audi’s “Mission:Zero“ environmental program. An example from Audi logistics: Wherever possible, packaging is avoided. And where packaging material is necessary, it is preferable to use recyclable and/or renewable resources. From 2030, the goal is to increase the proportion of recyclable packaging materials in new vehicle projects to more than 90 percent.

Reuse: enabling continued use

The reuse principle encompasses four approaches:

Remanufacturing: Used parts are comprehensively reworked and reconditioned.

Repair: Damage to defective parts is repaired, enabling reuse. This aspect is closely linked to the reduce principle: If it is possible to extend a car’s utilization phase through repairs, this also reduces the dependency on new primary materials.

Used parts: Used parts are installed to repair vehicles without being reconditioned beforehand.

Second life: Vehicle components are reconditioned for non-automotive use.

The following measures demonstrate how these four approaches are put into practice:

Remanufacturing: Instead of new parts, Audi owners have access to resource-friendly “Audi Genuine Exchange Parts”. The Exchange 2.0 program, for example, offers a sustainable remanufacturing method for the transmission mechatronics of the Audi S tronic models.

Repair: Through the “Audi Genuine Parts Repair” program, Audi customers can have defective parts repaired. The focus here is on infotainment instruments and dashboard displays.

Used parts: In the future, Audi customers will have access to a portfolio of replacement parts for carrying out repairs. Repairs following an accident are a key use case. For vehicles that have been involved in an accident, it is often not economically viable to replace all defective parts with new ones. However, more affordable used parts can make repairs a sensible option. This results in the continued use of vehicles that would otherwise have been totaled.

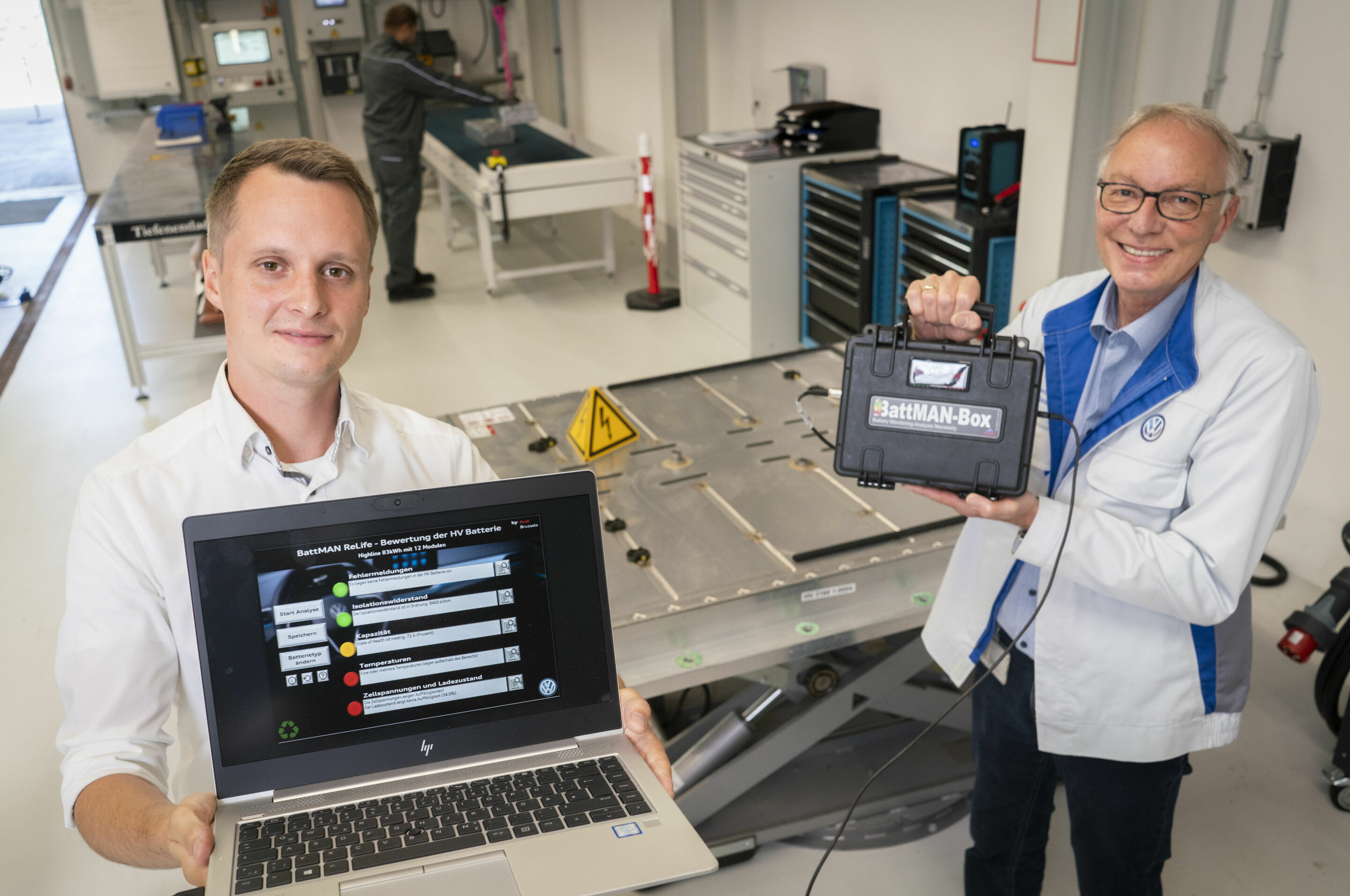

Remanufacturing and second life: The reuse principle is particularly important with electric vehicles, especially with respect to their lithium-ion batteries. Premature disposal of batteries makes neither ecological nor economic sense, since high-voltage batteries can continue to be used even after years of use on the road. To that end, Audi is pursuing two possible reuse objectives within the Volkswagen Group: firstly, remanufacturing, which entails the continued use of high-voltage batteries in electric vehicles. And secondly, so-called second-life concepts, which allow batteries to have a second life for years outside of an electric vehicle, for example in the fast-charging station of an Audi charging hub.

Recycle: the end as a new beginning

The recycle principle encompasses measures that affect the production of a vehicle and the phase following its end of life, if reuse ofthe vehicle or its individual components is no longer possible. The idea is to reuse as many materials as possible, preferably from end-of-life vehicles, as secondary materials, thus virtually eliminating downcycling.

Downcycling refers to cases when the quality of a new product made with recycled materials is lower than that of the original product. Audi aims to prevent this downward spiral of material quality.

As such, the company takes a two-pronged approach to recycling:

The recovery of secondary materials from end-of-life vehicles at the end of their utilization phase (end-of-life recycling). Such vehicles are first dismantled into their individual components, enabling the remanufacturing of used raw materials, ideally without any loss in quality.

The use of secondary materials in the new vehicle production process. The goal is to use secondary materials wherever it is technically feasible and makes ecological and economic sense, again without any loss in quality.

Audi takes a hotspot-based approach here, meaning the company focuses on materials and components with the greatest immediate impact. This includes aluminum, steel, plastics, glass, and components of high-voltage batteries.

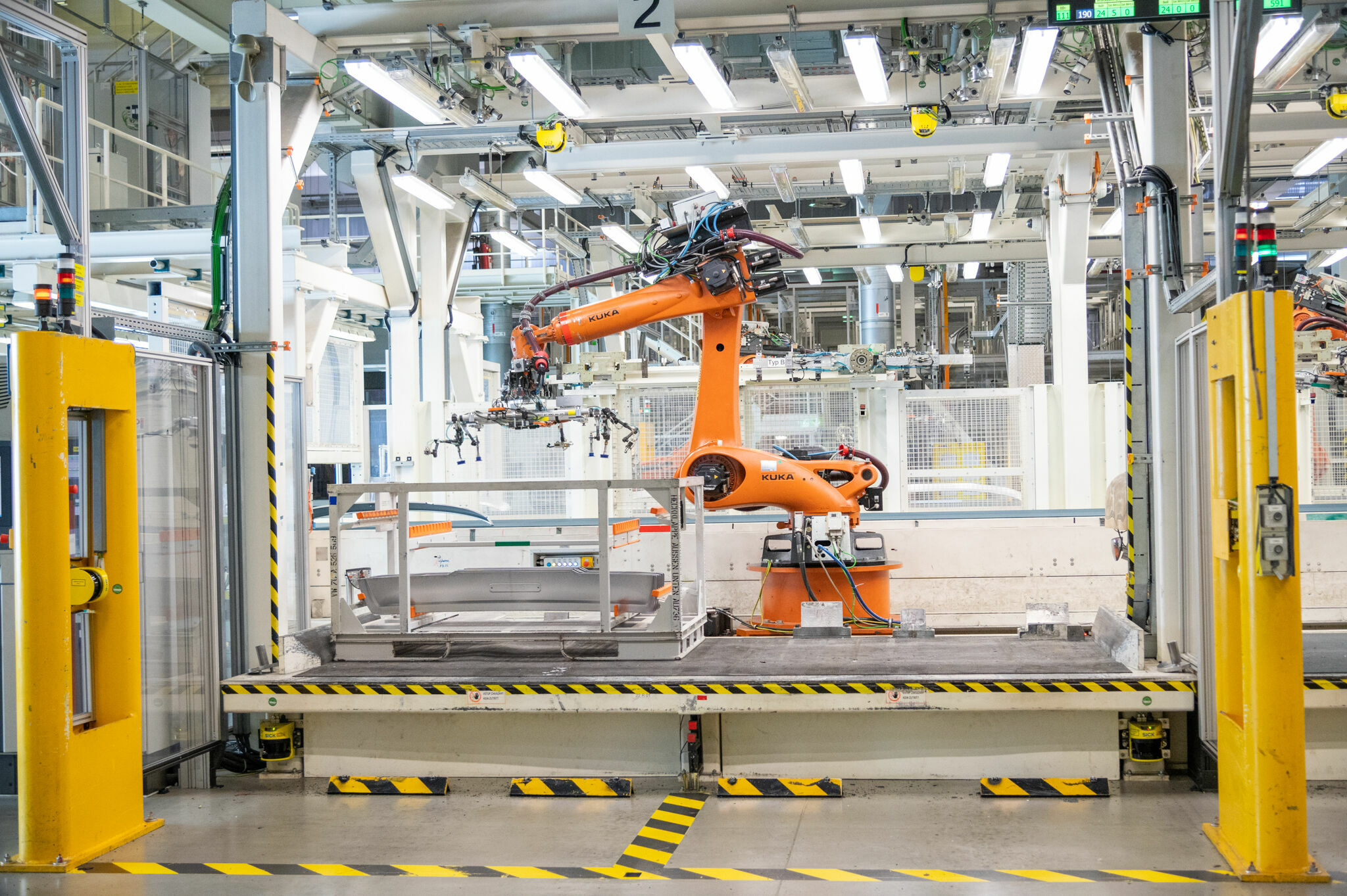

Steel: For the production of the Audi Q6 e-tron series, part of the steel used to manufacture components of the exterior skin comes from post-consumer sources1, including material recovered from end-of-life vehicles. The material is used to produce all variants of the exterior of the roof, and provides a first glimpse into how post-consumer steel scrap will be used in future vehicle generations.

Aluminum: In addition to keeping post-consumer secondary materials in a closed loop, post-industrial materials are also recycled. The primary goal in this regard is to reduce CO2 emissions. With the Aluminum Closed Loop launched in 2017, Audi is demonstrating the responsible handling of aluminum. Aluminum sheet offcuts produced in the press shop are returned to the material cycle. By recycling aluminum waste in this way, the company uses up to 95 percent less energy to produce aluminum than would be necessary for primary aluminum.

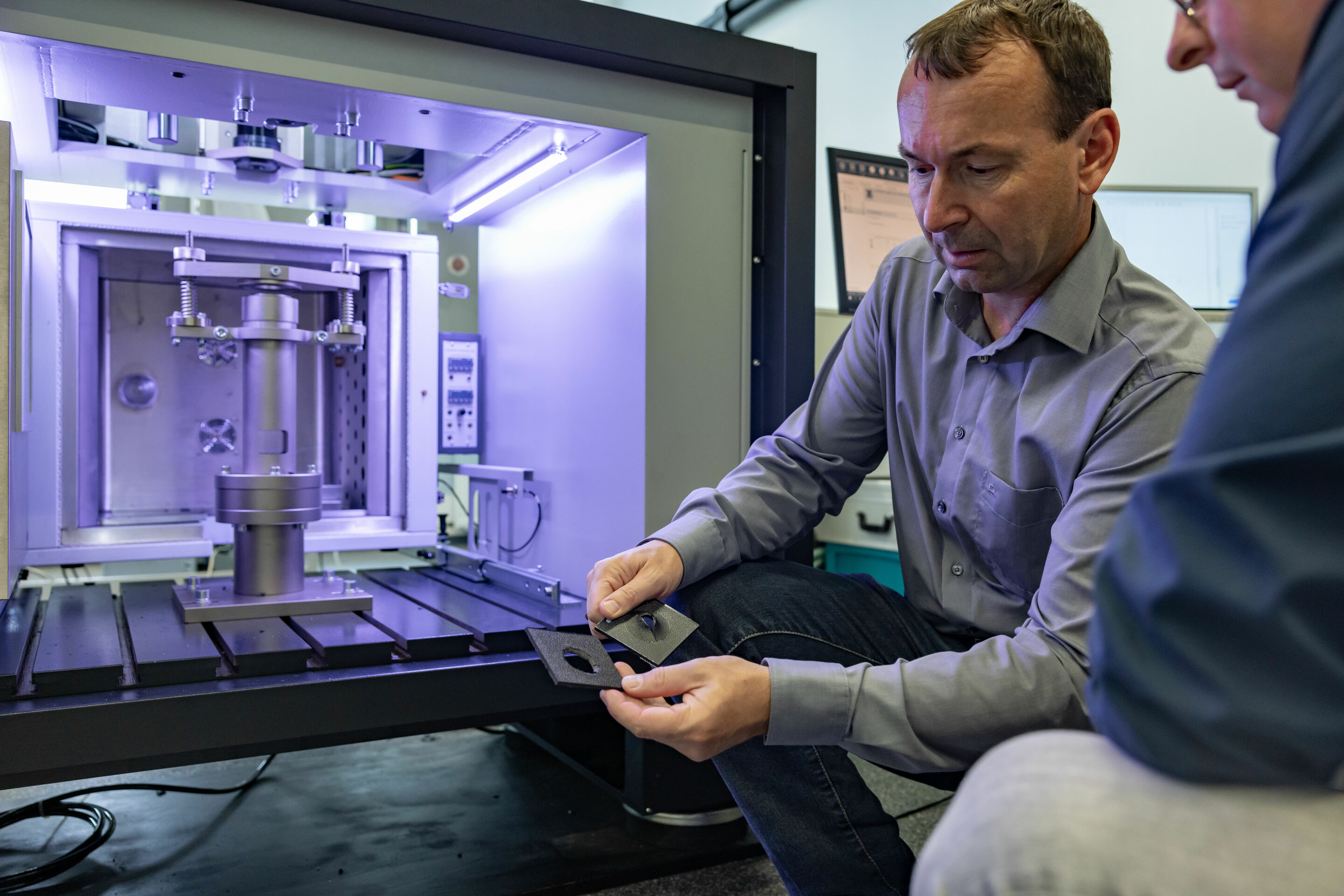

Plastics: Generally, modern vehicles contain more than 200 kilograms of various plastics and plastic composites. With the PlasticLoop project, Audi and plastics manufacturer LyondellBasell have established a process that uses a recycled material obtained from mixed automotive plastic waste through chemical recycling in series production for the first time. For the Audi Q8 e-tron, Audi uses safety-relevant components produced with a recycling process, namely the plastic covers for the seatbelt buckles2. The type of recycling used here is another process on top of mechanical and physical recycling: chemical recycling. The brand with the four rings has partnered with the Fraunhofer Institute to research chemical recycling in a pilot project, the first step of which dissolves plastic with solvents. Several additional process steps and drying result in a highly pure plastic granulate of new-product quality.

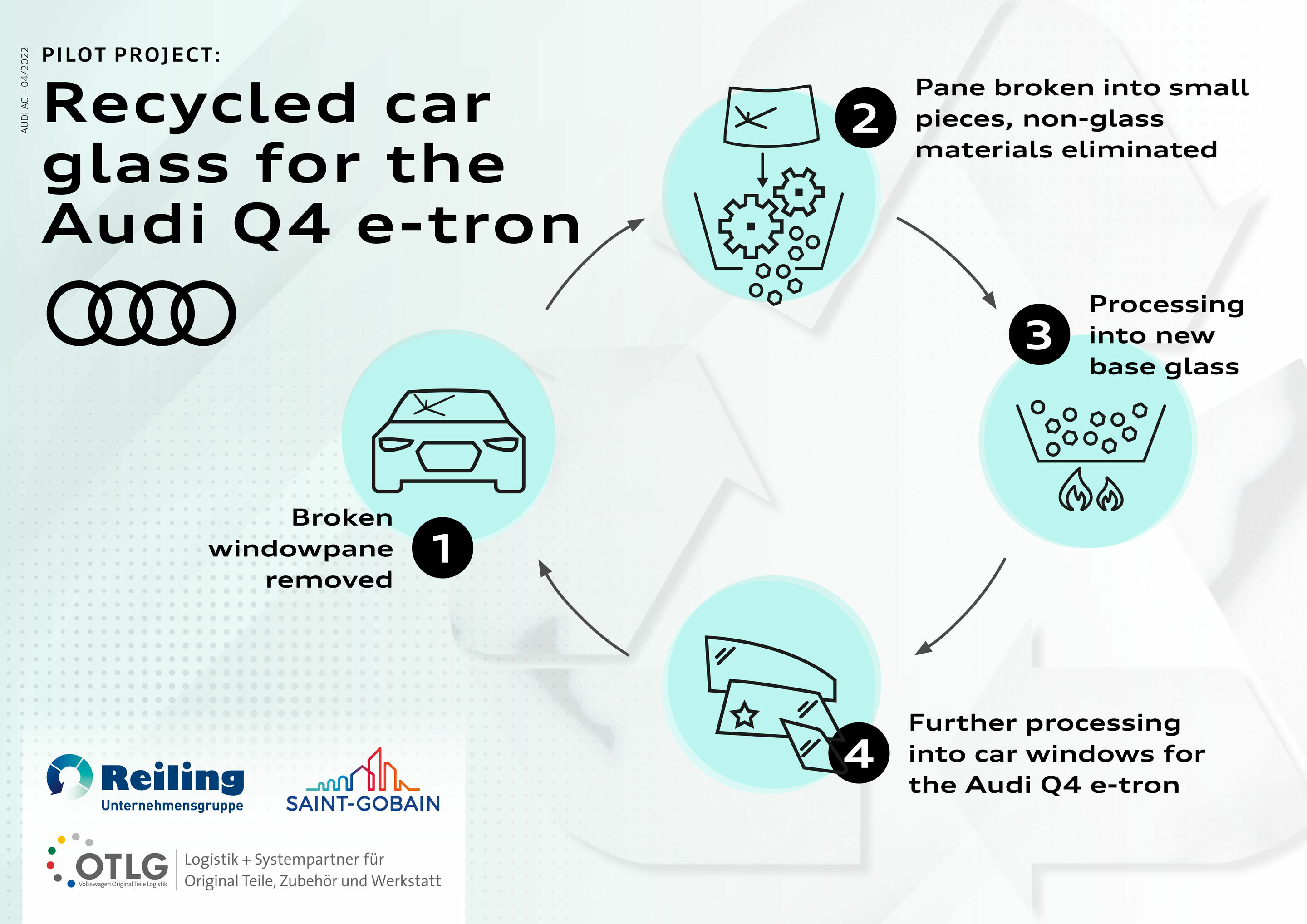

Glass: Together with Reiling Glas Recycling, Saint-Gobain Glass, and Saint-Gobain Sekurit, Audi has demonstrated with its GlassLoop project how material cycles can be put into serial production. The partner companies and Audi tested how to produce new windshields from defective car glass. Since September 2023, windshields made with recycled material have been used for series production of the Audi Q4 e-tron, where glass made of up to 30 percent recycled materials from irreparably damaged car windows is used for the windshields. In cooperation with its partner companies, Audi is the first premium auto manufacturer to set up a glass cycle of this kind.

Battery: Across the Group, Volkswagen AG is working on a recycling concept for batteries. Volkswagen is also exploring strategic partnerships with numerous actors in the battery value chain to comprehensively close the loop for the Group. The aim is the industrialized recovery of valuable raw materials such as lithium, nickel, manganese, and cobalt in a closed loop, in addition to aluminum, copper, and plastic. To this end, Volkswagen Group Components opened the Group’s first pilot plant for recycling high-voltage batteries at the Salzgitter site in early 2021.

End-of-life vehicle recycling: With the joint project MaterialLoop, Audi took the next steps towards closing material loops in 2022 and 2023. Together with 15 partner companies from the research, recycling, and supply sectors, the brand with the four rings investigated the reuse of post-consumer materials from 100 end-of-life vehicles to produce new vehicles. The focus was on testing the recyclability of steel, aluminum, and plastic.

In contrast to reusing post-industrial secondary materials such as offcuts from production processes, processing post-consumer recycled materials (such as those obtained from end-of-life vehicles) is more difficult. End-of-life vehicles contain a variety of mixed materials that must first be separated and remanufactured in time-consuming successive steps such as dismantling, shredding, and re-sorting (referred to as post-shredding technology). The pilot project tested the technical feasibility of this loop, and was successful: Through the project, Audi was able to reuse more than 60 percent of the aluminum and more than 85 percent of the steel obtained from end-of-life vehicles for the production of new vehicles.

This confirms the technical feasibility of the approach. In the successor project (start date: August 2023), Audi is developing a business model that will implement the technical concept in the future on a larger scale.

1 As part of Audi’s "Circular Economy Strategy", we are striving to continuously increase the proportion of recycled materials (so-called "recyclates") in our vehicles' various components. For the first time, Audi is using steel scrap recycled from products used by end consumers (post-consumer recyclates) to produce a body shell component, starting with the Audi Q6 e-tron.

The steel used in our production of all variants of the Audi Q6 e-tron's outer roof panel comes from a manufacturing process using 15% post-consumer steel scrap, including scrap from end-of-life vehicles. To this end, enough steel scrap is added to the steel production process to achieve an average post-consumer recyclate content of 15% in the steel used to manufacture the outer roof section (so-called mass balance approach). However, this means that the actual percentage of steel scrap used in the individual outer roof section of an Audi Q6 e-tron can also be less than 15%.

2 At least 70 percent of the plastic granulate used in seatbelt buckle covers (including fillers and additives) comes from the pyrolysis oil produced in the project. This pyrolysis oil is added to the plastic granulate during the manufacturing process. The allocation of the waste-based pyrolysis oil to the plastic granulate is carried out as part of a mass-balance approach with a qualified credit transfer. This means that ecocycle, an independent external certification body, has confirmed that the project members have replaced the quantities of fossil resources required for the seatbelt buckle covers with pyrolysis oil produced from mixed fractions of automotive plastics. It is intended to provide sufficient pyrolysis oil in the scope described above for the entire production life cycle of the Q8 e-tron on the basis of currently projected production figures.

As of: March 2024